The reason behind 3D printing not being able to become a mainstream technology is the speed. Although the 3D printing technology is often referred to as rapid prototyping process, printing something as basic as a glass could take hours. This slows down the working of an entire unit resulting in slowing of the entire consignment.

So in order to battle this out there is a new concept that has been developed by a German engineering student named Stephanie Mueller and her team at the Hasso Plattner Institute which had collaborated with the Cornell University to carry out this project.

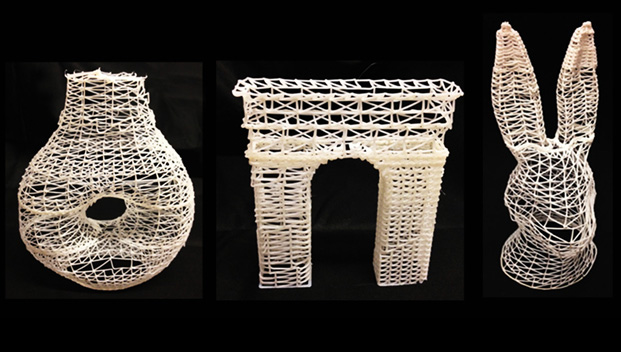

The concept of Low-fi fabrication allows the speeding up the prototyping process. In this low-fi fabrication process the standard layer build of a typical 3D printer is replaced by a wireframe mesh which copies the exact shape and dimension of the item to be prototyped. This reduces the printing time from two hours to fifteen minutes. Since material is extruded directly into the 3D space rather than printing in layers, this speeds up the process up to 10 times more as compared to the traditional 3D printing method.

As Mueller in her paper says, “To maximize the speed, we instruct 3D printers to extrude filaments not layer by layer, but directly in 3D space, allowing them to create the edges of the wireframe model directly one stroke at a time. This allows us to achieve speed ups of up to a factor of 10 compared to traditional layer based printing.” She further added, “WirePrint converts a 3D object into a wireframe representation by (1) slicing the 3D model along its vertical axis into horizontal slices and (2) extracting the contours. It then (3) fills the space between slices with a zigzag pattern. Unlike the traditional 3D printers that stack filament on filament, WirePrint creates its layers by moving the print head up and down repeatedly.”

With the help of this process users can create different types of mesh for different objects and depending on the shape, size and dimension of the object the print speed and strength of the object would vary. The strength of the object depends upon the pattern and speed, the faster meshes would be weak whereas if the pattern of the mesh is complex then the printing speed will be slow but the object thus produced will be strong. If the WirePrint method is amalgamated with the traditional printing process then a hybrid low- fi fabrication can be created.

All of the above features make this a very useful tool for beginners, hobbyists as well as professionals. The wireframe mesh is apt for materials that transform quickly from liquid state to solid state, making PLA the lesser preferred material over ABS. The only problem with ABS is that it has smaller temperature range as compared to the PLA material. For ABS the range is (230- 250°C), on the other hand for PLA the range of temperature is (180- 250°C).

This method not only saves time but also is quite economical on the material usage front. Leaving the user a happy user as the method is not only fast but is monetarily beneficial.

Sources:

http://www.3ders.org/articles/20140917-wireprint-3d-printed-wireframe-previews-speeds-up-prototyping.html

http://3dprintingindustry.com/2014/09/19/rapid-prototyping-isnt-rapid-enough-try-low-fi-fabrication/