Tolerance is one very important element in manufacturing. It is virtually impossible to design a product to the exact 3D design as manufacturing involves physical processes and thus it is next to impossible to create that perfect product. The variation between the dimension as per CAD diagram and the acceptable dimension in the physical product is what is called tolerance. Different manufacturing technologies can achieve different kinds of tolerances depending on the kind of machine being used, machine accuracy and material being used. Let us first look at 3 major manufacturing technologies available in the market currently – 3D Printing, CNC Machining & Sheet Metal Fabrication.

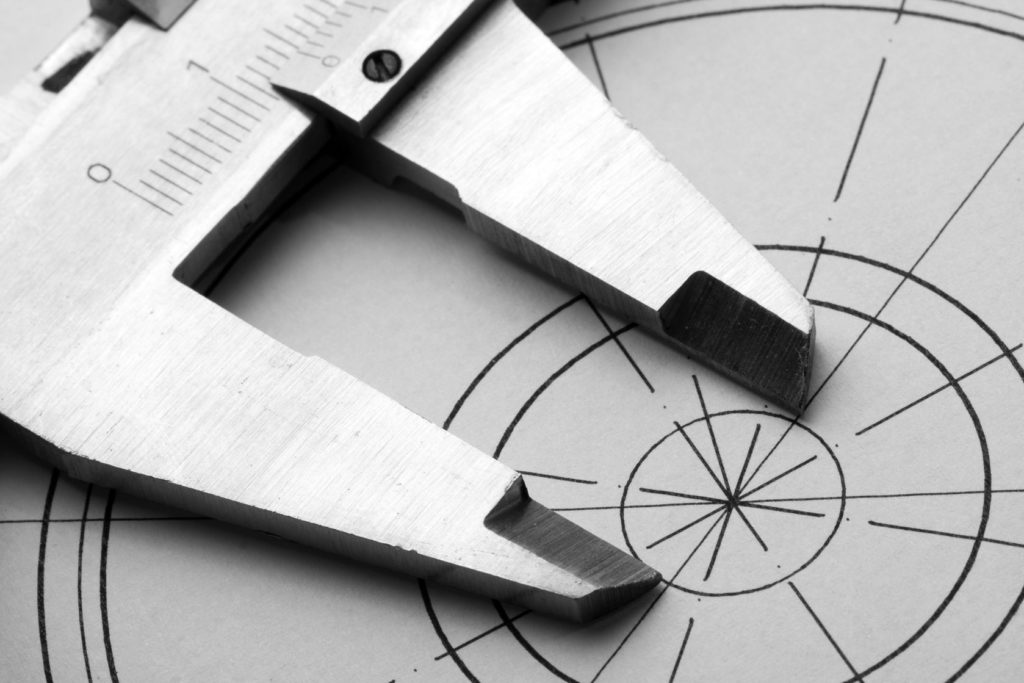

CNC Machining: CNC Machining provides highest tolerance of all technologies because of the way machines are operated. In CNC Machining process, material is cut from the block to get the required shape. In CNC Machining, a gantry is present that moves to the exact location and chips away the material. Since the machine movement is gantry based, the material shall be removed to the exact tolerance.

3D Printing: In 3D Printing, parts are manufactured through deposition of material. In 3D Printing, laser / infrared light / heated nozzle are used to add material layer by layer and create the final part. As 3D Printing is additive in nature where material is melted and fused, the tolerances achieved in 3D Printing aren’t as high as those achieved in CNC Machining. SLA technology offers the best resolution of all technologies. FDM offers the lowest resolution. Typical tolerance varies from 10 micron to 100 micron.

Sheet Metal: Sheet Metal provides the lowest tolerance of all because of the very nature of part production in sheet metal fabrication. Sheet Metal Fabrication involves bending the metal parts to achieve the desired shape. When bending the metal parts, the expansion / contraction of the part depends on the metal and tool in use and their respective tolerances. The part behavior varies depending on where the part is bent. If the part is bent closer to the edge, it expands at a different rate than when the part is bent far from the edge. In sheet metal fabrication, the tolerance on the surface is lot higher than the tolerance on the bent part.

To summarize the discussion, CNC Machining provides the best tolerance of these 3 technologies, then comes 3D Printing and finally sheet metal fabrication.