INJECTION MOLDING

- With two horizontal injection molding machines from Toshiba and 1 vertical injection molding machine, we provide injection molding service for various quantities and for different kinds of plastic materials.

INJECTION MOLDING

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

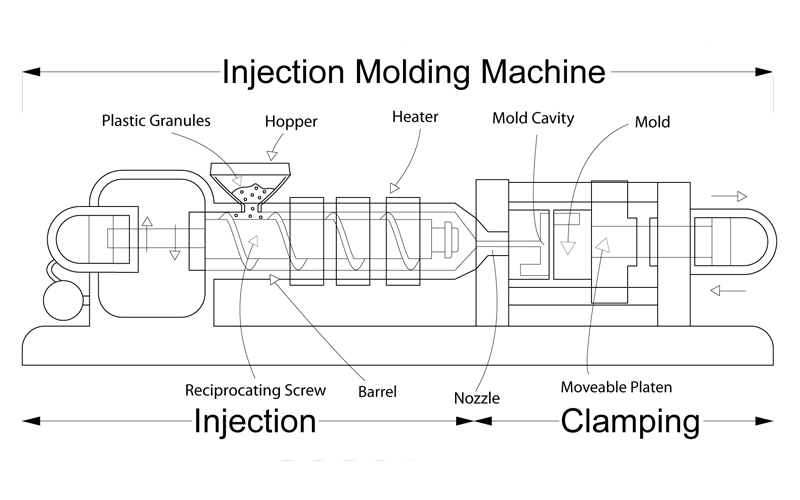

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a host of materials mainly thermoplastic and thermosetting polymers.

Material for the part is fed into a heated barrel, mixed and injected into a mould cavity where it cools and hardens to the configuration of the cavity.

After a product is designed, usually by an industrial designer or an engineer, molds are made by a mold-maker from metal, usually either steel or aluminum and precision-machined to form the features of the desired part.

Applications

- Low volume production

- Bridge tooling

- Pilot runs

- Functional prototyping

materials

ABS

| Tensile Strength (MPA) | Flexural Strength (MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 2.60 - 73.1 | 10.3 - 655 | 90 - 122 | 50.0 - 109 |

Acrylic

| Tensile Strength (MPa) | Flexural Strength(MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 19.3 - 85.0 | 33.1 - 143 | 69 | 50.0 - 100 |

PTFE Teflon

| Tensile Strength (MPa) | Flexural Strength (MPa) | Hardness, Shore D | Maximum Service Temperature °C |

|---|---|---|---|

| 13.0 - 333 | 14.0 - 27.6 | 11 - 70 | 93.3 - 316 |

PEEK

| Tensile Strength (MPa) | Flexural Strength (MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 50.3 - 265 | 86.2 - 380 | 4.28 | 20.0 - 310 |

Nylon 6

| Tensile Strength(MPa) | Flexural Strength(MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 3.45 - 100 | 7.00 - 200 | 73 - 120 | 70.0 - 250 |

Polycarbonate

| Tensile Strength (MPA) | Flexural Strength(MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 30.0 - 93.1 | 27.6 - 205 | 72 - 124 | 116 - 150 |

PET

| Tensile Strength(MPa) | Flexural Strength(MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 5.52 - 90.0 | 60.0 - 121 | 105 - 125 | 60.0 - 225 |

LDPE

| Tensile Strength(MPa) | Flexural Strength (MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 2.80 - 56.5 | 65.02 | 38 - 56 | 95.0 - 115 |

HDPE

| Tensile Strength(MPa) | Flexural Strength (MPa) | Hardness, Rockwell R | Maximum Service Temperature °C |

|---|---|---|---|

| 7.60 - 43.0 | 13.8 - 75.8 | 33 - 66 | 70.0 - 120 |

PLA

| Tensile Strength (MPa) | Flexural Strength (MPa) | Hardness, Shore D | Maximum Service Temperature °C |

|---|---|---|---|

| 0.160 - 3000 | 0.170 - 159 | 48 - 87 | 60.0 - 240 |

specifications

Mold maximum height: 560 mm

Mold minimum height: 200 mm

Mold platen distance: 800 mm x 800 mm

Tie bar distance: 500 mm x 500 mm

Shot weight: 400 grams

Injection pressure: 1930 Bar

post processing

- High quality finish

- Custom color matching

- Threaded inserts

- Pad printing

- Laser engraving

- Part assembly

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

Rotational molding, rotomolding, rotomold or rotocasting is a production process to form hollow parts of limitless size. This is a cost-effective method to produce large plastic parts. Resins are added into a mold that’s heated and rotated slowly, both vertically and horizontally.

A back pressure is the pressure in an injection molding machine that is exerted by the material when the material is injected into the mold.

Different plastics used for injection molding are:

- ABS

- Polypropylene

- Polyoxymethylene (POM)

- Polycarbonate

- Polycarbonate / ABS

- PVC

- Nylon

- Nylon 32% Glass Fiber

- Acrylic (PMMA)

- Styrene

- Polyetherimide (PEI)