CNC MILLING

- Our CNC milling process produces prototypes and end-use parts within 3 - 4 days. We use 3-axis, 5-axis and TurnMill processes to manufacture parts from more than 30 engineering-grade plastics and metals.

cnc milling

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

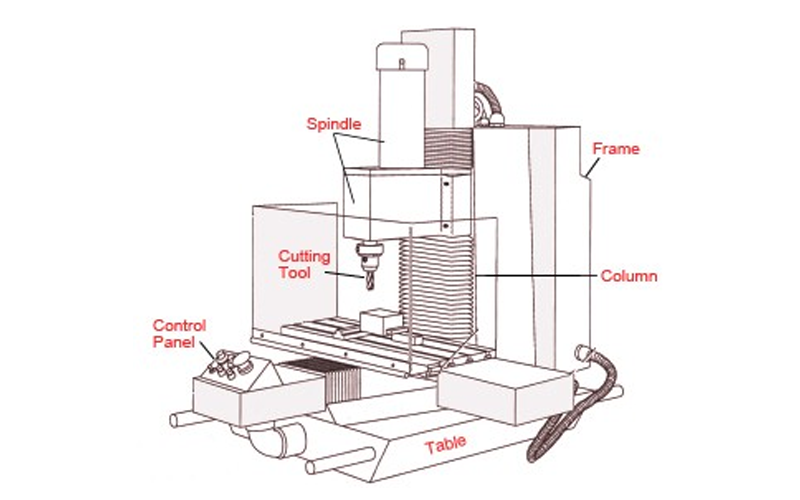

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Using G-code, the CNC machine is programmed to rapidly mill out parts from the block of raw material. Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency and production speed.

Machined plastic parts are left as-milled, which typically means they show visible tool marks. Some metal parts allow more finishing choices like anodizing and chromate plating. When the run is complete and your required surface finish is applied, parts are boxed and shipped shortly thereafter.

Applications

- Functional prototypes

- Jigs & Fixtures

- Production components in lower volumes

materials

Aluminium

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Stainless Steel

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Mild Steel

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Brass

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Copper

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Titanium

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Inconel

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Bronze

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

Cobalt Chrome

| Tensile Strength(MPa) | Flexural Strength(MPa) | Impact Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| - | - | - | - |

specifications

Maximum Dimensions (3 Axis Milling): 600 mm x 500 mm x 200 mm

Minimum Dimensions: 6.5 mm x 6.5 mm

Machining Tolerance: 0.005 mm – 0.010 mm

Recommended Thickness: 0.020 in. (0.51 mm)

Lead Time: Minimum 5 working days for despatch

Surface Finish: As per the requirement shared in the CAD drawing

post processing

Basic: Deburring, Buffing, Tapping, Lapping, Sand Blasting

Anodizing: Anodizing is an electro-chemical process that converts metal surface into a decorative, durable, corrosion resistant anodic oxide finish.

Chrome Plating: Chrome plating helps protect parts from corrosion while adding electrical conductivity and the ability to paint the part. Steel and iron based metals require pretreating with zince before applyign chromate.

Spray Painting: Spray painting is a painting technique in which a device sprays coating material (paint, ink, varnish, etc.) through the air onto a surface

Powder Coating: Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

CNC mills come in 3-axis, 4-axis, and 5-axis configurations:

Milling is suitable for many different features, including threading, chamfering, slotting, etc. This allows for producing complex designs on a single CNC milling centre with enviable accuracy. The tolerances for CNC machining are around +/- 0.1 mm.

The creation of these aforementioned features requires a variety of different milling operations:

- Surface milling

- Face milling

- Angular milling

- Form milling

- Profile milling

- Gear milling, etc.

Tool offset refers to the allowance made by a milling machine to design the cutting tool and shift its position. It ensures the CNC machine is operating on the right part of the workpiece.

Just like other CNC machining services serving their utmost to several industries around the globe, the CNC milling procedures and services are also working to their maximum to facilitate businesses and industries. Depending on the type of machined part, prototype scale, or production line, the following are some of the industries that are directly getting facilitated with the CNC milling services.

- Electronics industry

- Medical industry

- Automotive industry

- Marine industry

- Agricultural industry

- Machine tool industry

- Military industry

- High-tech industry

- Food industry

- Aerospace industry

- Semiconductor industry

Hence, CNC milling services are best to give your machined parts and prototypes a new dimension and fits in the big picture. Being a budding machining service, the CNC milling procedures are now carried out in machine shops to give a reliable, strong, and finished custom machined part.

1. Cost Efficient

80% of aspect and mechanical parts can be CNC milled within minutes or even seconds by optimizing the tool paths and using special cutting tools. With automation set up, CNC milling is super cost-efficient for mass production comparing with additive manufacturing in most of the cases.

2. Materials & Finishes Options

Besides of fast turnaround time, various type and spec of the plastic, metal block are available for milling, and different type of surface finishing is available for CNC milling parts, such as painting, anodizing and chroming. It’s great a combination of function and aspect.

3. Unlock Complexity

Because the cutting tool of a milling machine can approach the workpiece from several different angles, it is possible to create complex shapes CNC parts, with more axis, we can create parts of greater complexity. If a CNC project demands an irregular shape, milling is often the best bet.

While potentially any solid, stable material can be milled, we have a standard selection of raw material including hard plastics and aluminum, various steels, titanium, magnesium, brass, copper and other alloys.

Note that some hardened steels may be too hard to CNC machine, or else would require specialty cutting tools and longer processing times. Soft elastomers or plastics may also be impossible to mill since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

- Imported CNC milling centers and cutting tools offer repeatable precision on your projects.

- Staffed by skilled operators working with a team of toolmakers.

- We’re able to keep costs down while providing unmatched precision and quality without compromises.

- We work in a clean, well-lit and climate-controlled production area, certified to ISO9001:20015, ISO14001 and BS-OHSAS 18001 standards.

- We use best-in-class AutoCAD software for maximum efficiency and machine compatibility.

- Incoming quality inspection and testing of raw materials ensures the integrity of our supply chain, so you get exactly the materials you specified.

- We are experts in prototyping and low-volume manufacturing, so quick set-ups and rapid production is in our DNA.

- Our CNC milling services are designed to work in tandem with our many other in-house fabricating and finishing capabilities, to provide you with a comprehensive one-stop rapid manufacturing solution.

- We’re located close to major shipping ports in Visakhapatnam, so your parts can be on their way to you fast.

Rates vary with process and we employ many processes at THINK3D. Basing part or project costs on factory rates assumes all similar factory operate at same level of productivity employing the same level of employees and equipment. Certainly that is not the case. We prefer to provide pricing upon detailed review of your Drawings. This approach is much more valuable to the customer.

Average is difficult to define given the diverse nature of materials and processes utilized at THINK3D. We consider ourselves as a “Quick Turn&Milling” operation. Often providing much shorter lead times than typical industrial cutting or machining operations. Additionally giving the fact that we have so many processes in house it allows us to do the entire project (or a large piece of it) saving the customer the time and inefficiencies of utilizing several companies.

Depending on the part complexity and capacity of our company typical lead times range from 2-6 weeks after receipt of order.

Currently we can handle machined parts up to 850 x 510 x 510 mm.

3 replies on “CNC Milling”

Greetings,

I am looking forward to buy a CNC machine from you that can mill in 4-axis and able to work with materials like Wood, Al, Cu, Brass, Granite:

Please provide quotation for a suitable CNC milling machine available or customizable by you in any or all of the following work sizes:

Size A : 400 X 300 X 500

Size B : 600 X 400 X 400

Size C : 900 X 600 X 300

Size D : 1500 X 1000 X 200

Size E : 1500 X 1500 X 200

Looking forward to hearing from you soon.

Thank you.

Regards,

Neha Chandel

Conservation Architect

Ahmedabad

6006263807

Hi Neha Chandel,

We aren’t in the business of selling CNC Machines. So, we mayn’t be of much help here. There are many brands out there that sell CNC Machines like ACE Micromatics, HAAS, DMG Mori. You can reach out to them with the request. Hope this helps.

Would be delighted whether possible for a Die of 650mmX375mmX375mm at CNC milling machine available at your facility.