Ever experienced your 3D printed model not shaping as per what you expected ??? Keeping track of the parameters, hoping in your heart that you would get a perfectly shaped statue of your your role model which you may have taken hours to design. And yet the design was just not right !!!! We understand the feeling, and so we have some good news for you.

There’s a start-up which have been listening to your concerns, taking note of the often-faced problems and doing an extensive research so that the next you press the “Print” button, you may actually get a desired model….. Just as you designed, and you do not have to think “I’m not sure if I’ve put the fill right”.. We understand the feeling, ….. and so does 3D Matter, the eyes & brains behind this.

Arthur Sebert, Founder of 3D Matter, who’ve been behind this research for months, explains, that 3D Matter intends to focus on having more information on how the different parameters needs to be considered, including what type of filaments you should use to get the desired texture. It may come as one-stop for material functioning, along with information.

They have made series of charts which contain clear information on all the parameters to be considered for a successful printing. They have underwent months of trial and error method themselves to come to the following solutions.

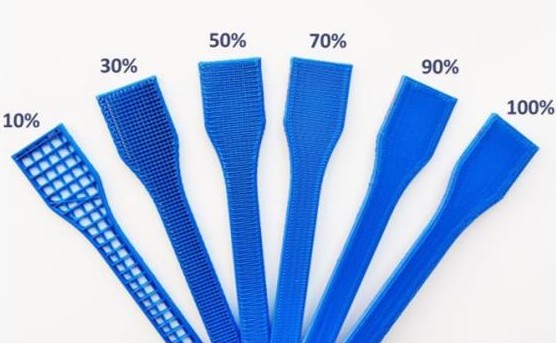

Different infills, all providing different results.

Arthur and company wanted to have a comprehensive understanding about the influence of infill %, layer height and infill pattern on the 3D print. To get to this, they figured in 3D printing they would be targeting two types of users, a) the average user group, giving them a clear idea on what they are getting against strength, quality, cost and speed, b) users who go little deeper, like understanding how the 3D printer is actually functioning and giving them detailed analysis of the different parameters to be considered. Also what parameter will have what kind of influence on the performance.

Arthur has explained what the different values actually denote. Meanwhile we will quote you what he said about understanding certain aspects, including how to measure cost. He said, “Strength corresponds to the maximum stress the specimen can take before breaking. Speed describes the printing time of a specimen. Cost is derived from the actual weight of the specimen, and assumes 30€/kg. Quality relates to the general aspect of printed parts based on their layer height. Quality is not the focus of this study but the relationship between quality and layer height is generally accepted.”

Now you know if you want only Strength then 100%. if you want Quality then reduce infill to 10%, if you want both then infill 90%. Useful isn’t it ?!

Below you’ll find a table with more detailed info on what are the probable results of the different percent of infill and Layer you choose.

They have also studied on the different patterns – Linear, Diagonal, Hexagonal, Moroccan stars and Catfill.

Linear: Most durable

Diagonal & Hexagonal = Sort of durable

Moroccan stars & Catfill: Worst

“We show that generally, the best patterns to use are Linear or Diagonal (=Linear tilted 45°)”. They explain, thus continuing, “Indeed, decorative patterns such as Moroccan stars and Catfill show poor performance and should only be used if they are exposed and are part of the design,”

These parameters should be able to help any 3D printer to learn better, whether he’s a novice or experienced to minimizing the cost, time and energy. And can sooner it can be a manual for starters, unless you are among those who find more joy in discovering them, which is great too.

Have you started to think3D yet !?