3D printing involves mammoth designing challenges. The researchers at the Newcastle University have unveiled their RMADS for Matlab. This consists of an extensive system which advice users on the most cost effective and lucrative design system.

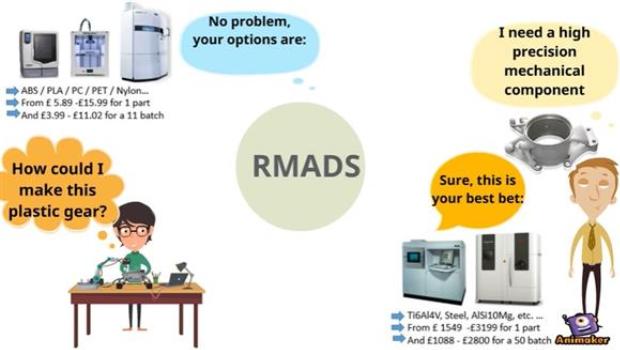

RMADS (Rapid Manufacturing Advice System) is a plan that is beneficial to the amateur users who want to use the technique of 3D printing but lack the technical expertise. It gives tips on using the right material for 3D printing and the correct printer for the printing process. Users can now get a solution to their query by calling the RMADS system. This system has an inbuilt logic mechanism that decides the rank of the processes, materials, and other details. Newcastle University researcher Javier Munguia said that the code was initially written for EU design projects like KARMA and AFOOTPRINT. The AFOOTPRINT project was commenced in 2014. It used the code to generate and 3D print custom foot supports for patients with foot and ankle problems.

As per the researchers, the demand for such a system started increasing. Even private sectors were looking up to a viable solution. Therefore, instead of coming up with a custom code for various companies, The Newcastle team decided to release the RMADS Code as an open source code. Using this code, users from various sectors could find solutions to their 3D printing problems.

Munguia further stated that the code was not PDM software. RMADS is, in fact, front-end software that helps new users with the 3D printing options for their product. The code has ‘relational databases ’which allows for users to make an initial screening of their 3D printing plans and select alternatives by comparing available material properties and costs.

The code can be downloaded from Github. It needs a MatLab or any other code-converting application.