Introduction :Injection Molding is one of the 3D printing processes used for producing parts by injecting molten material into the mold. This is used for producing high volume parts. The mold may be two plates or three plates depending upon the type of component to be manufactured.

Materials used :Acrylonitrile Butadiene Styrene(ABS), Polycarbonate (PC), Polystyrene(PS), Polyoxymethylene(POM), Polypropylene(PP), PVC, Nylon, Nylon 32% Glass Fiber, Acrylic.

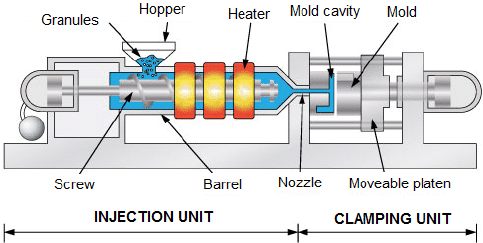

Parts of injection molding process:Hopper – The granules are inserted into the section.

Screw – The screw pushes the granules in the forward direction.

Heaters – These heating elements which are present in the barrel are used to melt the material at a certain temperature.

Nozzle – The temperature of the material increases so that it can move quickly into the mold.

Extraction Pin – This is used to remove the mold.

Coolers – Coolers are used to cool the melted material.

Injection Unit – This is used to inject the material into the mold.

Process:Firstly the process begins with Poly Carbonate granules being fed via a hopper, which is the entry point for the material. And then the screw rotates and pushes the granules forward. Now the granules are heated and melted inside. In between, there are heating elements that are used to melt the material. Now the molten plastic is injected through the nozzle into the core and cavity plates of the mold. After the material cools and solidifies, the mold opens. Finally, the molded part is ejected. The melted material should be distributed evenly into the mold. This process is used for producing high volume parts.

Advantages:

High Efficiency: Within a short span of time more quantities of molds can be produced. So that we can deliver our product on time. In this way, high efficiency is achieved in injection molding.

Low Labor Costs: As everything is automated and runs with the help of tools there is no need for too much labor. The overall process is maintained or kept under control with the tools. So automation helps to reduce labor costs.

Complex Part Design: We can manufacture even complicated designs or parts easily with the help of the injection molding process.

Fast Production: We can produce a large number of products in a single phase.

Low Waste: The left-out material is mostly recycled so in this way waste is reduced.

Disadvantages:

High Machinery Cost: The machinery cost is so high in this process. Initial costs are high because of designing, testing, and tooling.

Molds are Costly: The molds used in the injection molding process are costly. So this is one of the drawbacks of this process.

Why is injection molding used?

Injection molding is one of the desirable methods due to its simplicity and ease of the process.Here are some of the reasons why it should be used.

Cost-effective: As the process is automated, manufacturing costs are reduced. Due to Computer-Aided Design(CAD) we get accurate parts.

Fast: The injection molding process generally takes around 15-30 seconds for producing a part. This results in a faster rate.

Sustainable: Injection molding is an eco-friendly process. As the material used is plastic, it can be recycled. So in this way, it is sustainable.

Applications :Construction, Foods and beverages, Pharmaceutical

Products made with injection molding:

1.Electronic items: Injection molding used in electronic items such as computers, televisions, remote control devices.

2.Household items: Drinkware, containers, brush, bucket, mug, windows, doors, flower pots, toys, etc.

3.Medical: Test kits, surgical products, X-ray components ,needles, tubes ,blades etc.

4.Construction: Windows ,doors ,locks ,handles ,insulators etc.