Carbon nanotubes( CNTs) will soon be used to create conductive composite materials using 3D printers. A team of researchers at the University of Turin, led by Professor Marco Sangermano has been using a 3D printing technique called Digital light processing (DLP) which works with light projection and photopolymers.

The research, named “Development of 3D printable formulations containing CNT with enhanced electrical properties,” was recently published in the journal Polymer and is aimed at realizing 3D printable polymer nanocomposites. Carbon nanotubes are carbon-based, tube-shaped materials that have nanoscale diameters. The researchers carried out various tests by creating a matrix made of two different polymers PEGDA and PEGMEMA and added carbon nanotubes to it. The material mix was tested in its liquid form and the one with the ideal viscosity was used for 3D printing purposes using standard DLP 3D printer.

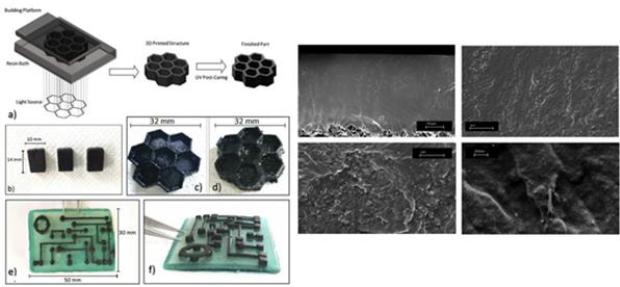

Three-millimeter cubes, centimeter-scale hexagonal structures, submillimeter films, and a circuit model were printed in the research tests. The conductive and mechanical characteristics of the carbon nanotube polymer composite were tested by creating these objects.

The tests inferred numerous findings:

• It was discovered that when CNT was added to the material mixture, it resulted in a minor decrease in crosslinking density, which further lowered the objects’ mechanical performance.

• Electrical tests results showed that by adding even 0.1 wt% CNTs to the polymer mixture the material’s conductivity was increased by three orders of magnitude (1000 x).

• When the concentration of CNTs was increased, the conductivity increased even more.

The Italian scientists are researching further in this respect, and we are eager to see new findings and discoveries in this field. They are trying to increase the mechanical properties of the carbon nanotube composites while still maintaining their electrical properties. For this purpose, they are using more intense light sources to perform the tests.