We are all fascinated by the lives of astronauts, going by the glamorous videos we get to see in science channels, with all of them floating in the air and doing strange things. Ever wondered about their needs will be, how they are able to stay in those capsules for months together and what happens in case of any technical glitches?

Space agencies like NASA spend billions of dollars to make the spare parts available on the space station in abundance, as they never know what they’ll need. In spite of this, there will be occasions where you need a tool and it is not available, leaving the astronauts to wait for weeks or months before they get the required replacement part to fix a machine there.. And, any small mistake might prove fatal at such a place.

Now, 3D printing is coming to the rescue in these complex situations. Any new part requirement can easily be designed from earth and transmitted to space, which can be used by the astronauts to print. NASA is planning to have a 3D printer in the space station, to give astronauts the ability to create custom parts exactly when they need them. A 3D printer can be handy in repairing space suits, printing extra bolts and nuts, and even some replacement parts which otherwise, should have to be sent from earth.

Made In Space is building a 3D printer for NASA to be used in ISS. The Mountain View-based startup firm which was founded in 2010, developed the first version of a printer for NASA in 2012. During the development phase, the printer was tested on parabolic flights, where brief episodes of near-weightlessness mimic the microgravity aboard the ISS.

Now, the printer passed its final NASA test ahead of schedule, which means the planned launch date forward by 3 months, from November to August. The printer will leave Earth aboard SpaceX’s fourth resupply mission to the ISS. Its first task aboard the ISS will be to print 21 test parts, video of which will be sent back to Earth and analyzed. Once the first task also becomes successful, Made In Space will focus its energies on increasing its build volume and adding new printing materials.

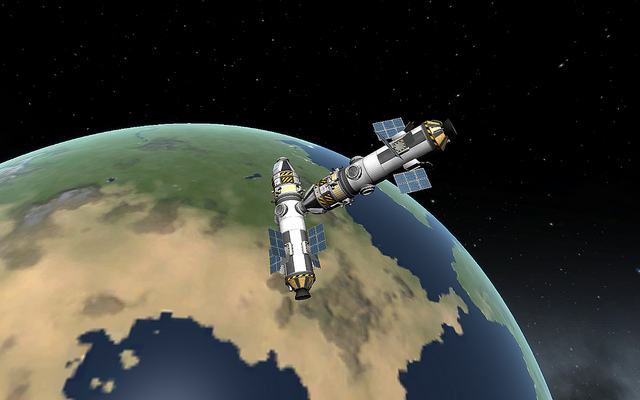

Image Credit: Les Chatfeld (flickr handle: elsie) Chriſtopher Chen(flickr handle: lumachrome