COMPOSITES

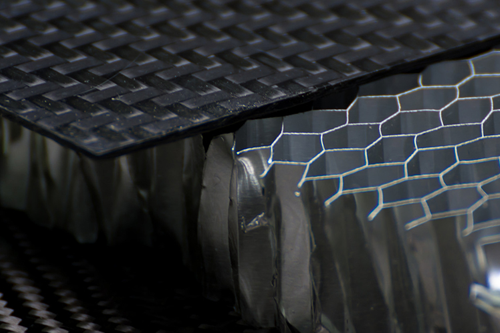

- A composite material constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements.

About composite Materials

Carbon fiber, fiberglass, and Kevlar are three of the most common fiber materials used for composites in industry. As we covered in the Physics of 3D Printing, the fibers are like spaghetti – thin, brittle, and easy to snap if bent. These fibers are almost never used by themselves – they are woven into sheets, wrapped into rods, or formed into custom molded shapes with the help of a matrix material to harden the fibers into an optimized shape. When many fibers are bound together to create larger structural elements, forces can distribute and disperse loads along the lengths of all of the fibers.

Composite materials types avaialble

| Type | Description | Process | Tolerance | Advantages |

|---|---|---|---|---|

| Carbon fiber-filled | It is considered by many to be the most efficient fiber for creating composite materials. Indeed, materials made from this fiber have high stiffness, high tensile strength and good chemical resistance | Natural | 100 - 150 microns | Light weight & High strength |

| Fiberglass-filled | fiberglass offers good mechanical properties. In addition, it is considered to be a good electrical insulator and has low thermal conductivity. It is more comparable to other polymers: for example, it is 11 times more rigid than ABS | Natural | 100 - 150 microns | Light weight & High strength |

| Kevlar-filled | One of the most wear-resistant materials, known best perhaps for being one of the first materials used for bulletproof vests. With good mechanical properties in traction and fatigue, Kevlar is mainly used to manufacture parts exposed to strong vibrations and needing to resist abrasion | Natural | 150 microns | Abrasion resistant |

Quick Overview

| Processes | Lead Time | Color | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| CNC Machining | As fast as 3 days | White & available in all major colors. | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium | Qty & Precision dependent | Impact-resistant applications, production-like parts (pre-injection molding) |

| 3D Printing | 2-4 Days based on size | White & available in all major colors. | FDM - 150 µm SLA - 40 µm | Lowest in market | Strength & complex geometries |

| Injection Molding | 20-30 Days | White & available in all major colors. | As low as +/- 0.030 mm | Qty & Precision dependent | High strength, Good surface finish. |

Design Recommendations

| Services Name | Max Size | Min Size | Min Thickness | Undercuts | Radii Depth |

|---|---|---|---|---|---|

| For CNC Machining | Max Part Size: 600 mm | Min End Mill Size: 0.8 mm | Min Wall Thickness: 0.5 mm | Undercuts: Square profile, full radius, dovetail profiles | Radii: Depth: Depth must not exceed 12x drill bit diameter. For end mills, depth must not exceed 10x tool diameter. |

| For 3D Printing | Max Part Size: 500x500x500 mm | Min Hole size : 1 mm | Min Wall Thickness: 1 mm | Min Feature Size : 3 mm | Recommended fillet & Chamfer angles : > 45 Deg |

| For Molding | Max Part Size: 500x500x500 mm | Min Hole size : 0.5 mm | Min Wall Thickness: 0.5 mm | Ribs should be 40-60% the thickness of outer walls and should still maintain draft | Minimum draft angle of 0.5°, or up to 5°, for faces with medium textures |

Frequently Asked Questions

Continuous carbon fiber 3D printing is strong enough to replace aluminium at half the weight.

- High-Strength Tools & Fixtures

- Brackets & Mounts

- Inspection/CMM Fixturing

- Bespoke End-Use Parts

- Functional Prototypes

In 3D printing, it’s possible to print with two reinforcement types of fibre, chopped and continuous. In the case of chopped fibre, small strands, less than a millimetre in length, are integrated into the polymer material. The percentage of fibre used, and the base thermoplastic determine how strong the final part is.

In the case of continuous fibre, long strands of fibre are mixed with a thermoplastic, like PLA, ABS, Nylon, PETG and PEEK during the printing process. Parts 3D-printed with continuous fibre are extremely lightweight, yet as strong as metal.

Yes

But composite parts are light weight in nature with improved properties.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL