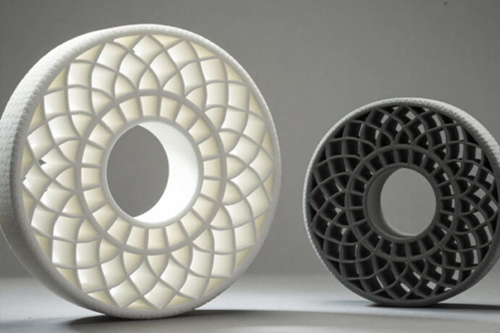

Thermoplastic elastomers (TPe)

- TPE material is developed for production of durable elastomer parts. The material enables prototyping of high functioning, durable and complex parts with the expected material properties found in an elastomeric material, including superior tear resistance, fatigue and memory recovery.

About TPE Material

Thermoplastic elastomers (TPEs) are a form of thermoplastic polymers. They are also a class of copolymers, or a physical mix of rubber and plastic polymers, that consist of both thermoplastic and elastomeric properties. TPEs are also referred to as thermoplastic rubber, as it exhibits some of the performance properties of rubber.

TPEs are soft to the touch, so they are ideal for a variety of markets and consumer goods. Furthermore, soft thermoplastic elastomers are easy to mold and extrude onto other TPEs. As a result, they are ideal for soft grips on products as well as sealing rings and bottle cap liners.

Quick Overview

| Processes | Lead Time | Color | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| 3D Printing | 2-4 Days based on size | White & available in all major colors. | FDM - 150 µm | Lowest in market | Strength & Flexible parts |

| Injection Molding | 20-30 Days | White & available in all major colors. | As low as +/- 0.030 mm | Qty & Precision dependent | High strength, Good surface finish. |

Design Recommendations

| Services Name | Max Size | Min Size | Min Thickness | Undercuts | Radii Depth |

|---|---|---|---|---|---|

| For 3D Printing | Max Part Size: 500x500x500 mm | Min Hole size : 1 mm | Min Wall Thickness: 1 mm | Min Feature Size : 3 mm | Recommended fillet & Chamfer angles : > 45 Deg |

| For Molding | Max Part Size: 500x500x500 mm | Min Hole size : 0.5 mm | Min Wall Thickness: 0.5 mm | Ribs should be 40-60% the thickness of outer walls and should still maintain draft | Minimum draft angle of 0.5°, or up to 5°, for faces with medium textures |

Frequently Asked Questions

TPE can be more recyclable, flexible, and softer than TPU. However, they do offer lower resistance to abrasion, grease/oils, chemicals and high and low temperatures.

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties.

220 – 250 °C

ACIDS (excluding carboxylic acids), Alcohol, METHANOL and ETHANOL (moderate concentrations) – GOOD

Bases, Tensides, Oil in water – EXCELLENT

Carboxylic acids, Fatty food, Water in oil, Aliphatic hydrocarbons, Polar hydrocarbons, Oil – SWELLS

3D printed TPE parts are not recommended to use in water resistant application.

Where as injection molded parts are water resistant.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL