AGILUS

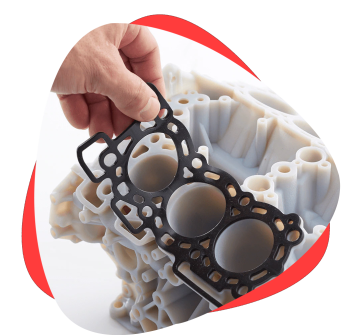

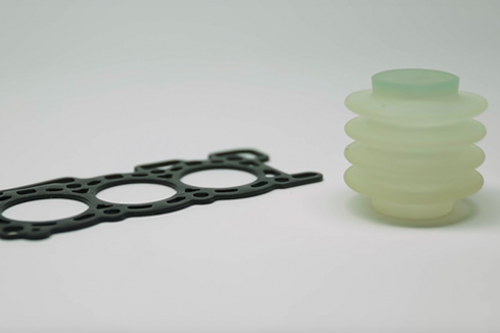

- Agilus30 is a PolyJet Photopolymer with superior tear-resistance, capable of withstanding repeated flexing and bending. The ideal material for rapid prototyping and design validation, this rubber-like material simulates the look, feel and function of rubber-like products.

About Agilus Material

Rubber-like PolyJet photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear or black, Agilus30 accurately simulates the look, feel and function of Rubber-like products.

3D print rubber surrounds, overmolds, soft-touch coatings, living hinges, jigs and fixtures, wearables, grips and seals with improved surface texture.

Quick Overview

| Processes | Lead Time | Color | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| 3D Printing | 2-4 Days based on size | White & available in all major colors. | 100 - 150 microns | Lowest in market | Flexible parts with controlled shore hardness. |

Design Recommendations

| Services Name | Max Size | Min Size | Min Thickness | Undercuts | Radii Depth |

|---|---|---|---|---|---|

| For 3D Printing | Max Part Size: 200 x 200 x 150 mm | Min Hole size : 5 mm | Min Wall Thickness: 5 mm | Min Feature Size : 5 mm | Recommended fillet & Chamfer angles : > 45 Deg |

Frequently Asked Questions

Agilus30 has a Shore A value of 30 in clear or black.

Don’t expose Agilus30 to water for too long. It is recommended that Agilus30 matte surfaces are not exposed to water for longer than one hour, as this will weaken the material and produce less than desired performance.

At room temperature, parts printed with Agilus30 have optimum elasticity. At very low temperatures, parts might become stiff and brittle, which should be considered when packaging parts and models for shipping. (Parts regain their original elasticity when warmed above 42°F/5°C.)

It is important to note that Agilus can merely mimic the properties of rubber and it is not a direct rubber replacement. Agilus cannot hold up to the same prolonged stresses and strains that a typical rubber can, but it can mimic the rubber properties in a part. The benefit is that it takes a significantly less amount of time to create a part versus the traditional manufacturing methods.

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL