Category: Learning Center

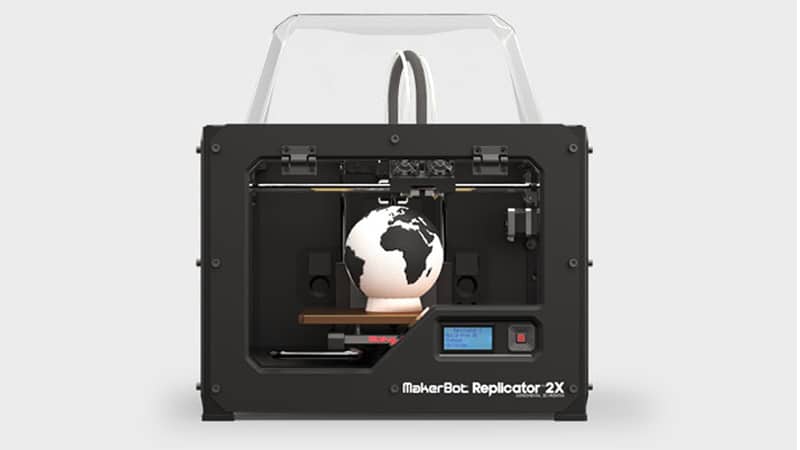

How 3D Printing is changing the state of Manufacturing Industry

July 20, 2014

No Comments

Read More »

LittleRP or LittleDLPer – Affordable Open Source 3D Resin Printer

July 19, 2014

No Comments

Read More »