Time and again it is proven that 3D Printing shall help in achieving social good esp. for physically challenged people. Traditional manufacturing doesn’t cater to that group as numbers are low and thus costs are high to manufacture good suited for the physically challenged segment of the population. This is where 3D Printing comes handy. Here is one very interesting project on using 3D Printing to help visually impaired kids learn concepts faster. We got a chance to meet the team behind the project and learn more about what they are doing and how 3D Printing helped them. Below are the thoughts from FITTLE team on project and how 3D Printing helps.

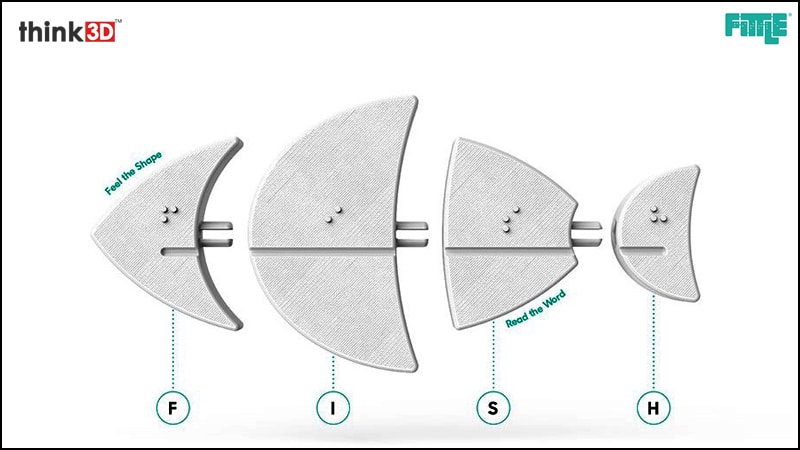

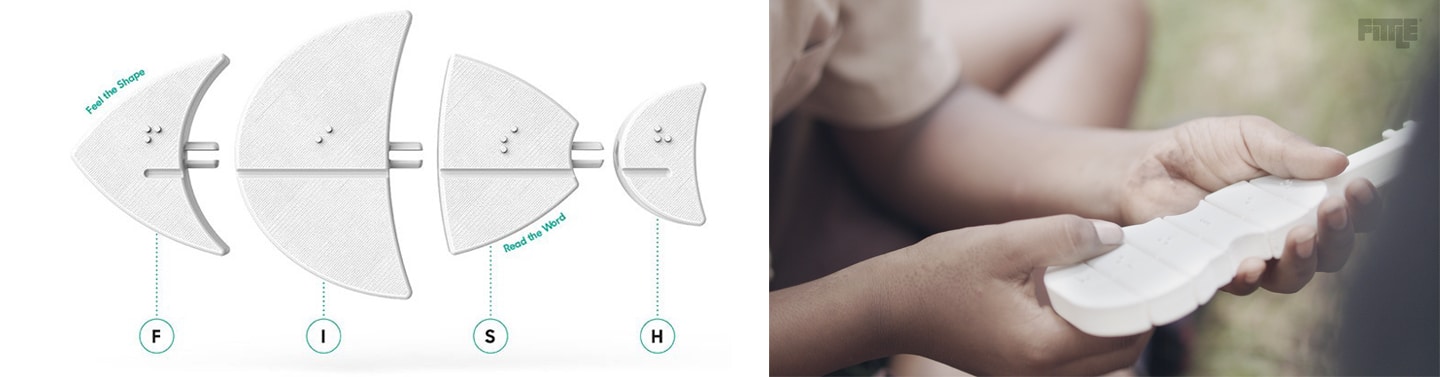

FITTLE is the world’s first 3D Printed Braille puzzle. A new way for the blind and visually impaired to learn and discover. Because FITTLE models are available open source to be simply 3D Printed at almost zero cost, learning Braille becomes more accessible than ever. There is a growing range of FITTLE models, covering the whole alphabets created by experienced puzzle designers for the most engaging learning experience.

Access to education makes a difference everywhere, but especially in developing countries. The first goal for the FITTLE project is to bring 3D Printers to schools for the blind and visually impaired in India. Discover how much joy FITTLE is already creating.

1) Can you give a brief overview of the project you are working on?

FITTLE is world’s first 3D printed Braille puzzle and was designed to make learning Braille playful for children with visual impairment. It’s an open source project. Various 3D Printable Braille puzzles are available for download on www.fittle-project.com. Anyone can download these puzzles, 3D Print them and use these as aids to teach Braille to children with visual impairment.

2) Why did you choose 3D Printing technology for the project?

For the kind of puzzles we design and the volumes we go for, it is highly economical to use 3D Printing over other traditional manufacturing methods. Also, you can replace the parts very easily and it is very easy to prototype and design.

3) Have you evaluated other technologies to achieve your goals, if so, what are those?

initially we thought of using wood to create the puzzles but that would lead to lot of manual work escalating the cost of puzzles. We realized 3D Printing is far more convenient to create those puzzles. So, we went ahead and used 3D Printing technology to create the puzzles.

4) Did 3D Printing meet your expectations in terms of quality / project outcome?

Yes, 3D Printing is an amazing technology that helps you kind of be very creative about your ideas. We were able to rapidly build the models, test the connectors, test the orientations. Thus 3D Printing has been of great benefit to us. As ours is an open source project, anyone can download those designs and use 3D Printer to print them. So, that’s the idea of making it both open source and 3D Printable.

5) Which 3D Printing technology & which machines are you using for the project?

We are primarily using FDM technology and been using wide range of printers from Makerbot to Ultimaker. We are currently using Ultimaker 2 and it has been a great experience so far with this machine.

6) Can you elaborate on your future plans for the project & how 3D Printing fits into those plans?

Future plans for FITTLE include building a global database of 3D Printable puzzles and translate the portal into as many languages as possible so that people across the world can download these design and 3D Print them. All the designs are 3D Printable and thus anyone with 3D Printer can print these designs and use the printed ones to teach the visual impaired ones.

We are looking to raise funds for us to be able achieve all of this. So, you can donate online at http://www.fittle-project.com/ to enable the solution reach hands of every child with visual impairment. Join this movement as we intent to create the world ‘s largest repository of the 3D Printed Braille puzzles for children to use in the future.

For more details, please contact info@think3d.in or call to +91 81428 96564