3D PRINTING IN AEROSPACE

- Scale Models

- Concept Models

- Interior Design

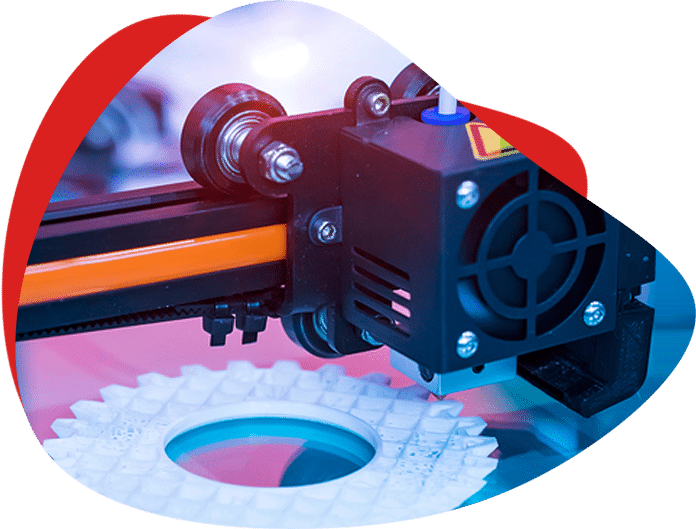

AEROSPACE 3d printing

3D Printing has wide applications in architecture industry. It is used for scale model manufacturing, concept model development, prototyping, interesting interior design works, concrete 3D Printing and so on. At THINK3D, we have been using 3D Printing technology in architecture industry for the last 6 years and have gained the required expertise. Please contact us to learn more about 3D Printing in architecture.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

AEROSPACE industry

Metal 3D Printing

Aerospace Tools & Fixtures

CNC Machining

Aerospace Materials

aerospace APPLICATIONS

| Materials | Description |

|---|---|

| Titanium | Available through machining and 3D printing services, this lightweight and strong material offers excellent corrosion and temperature resistance. |

| Aluminium | Aluminium's high strength-to-weight ratio makes it a good candidate for housing and brackets that must support high loading. Aluminum is available for both machined and 3D-printed parts. |

| Inconel | This 3D-printed metal is a nickel chromium superalloy ideal for rocket engine components and other applications that require high-temperature resistance. |

| Stainless Steel | Stainless Steel has wide applications in aerospace industry due to its high strength, good corrosion resistance and good mechanical properties at temperatures up to 600°F. Like titanium, it can be machined or 3D printed. |

| Liquid Silicone Rubber | Our liquid silicone rubber is specifically geared towards fuel and oil resistance while our optical silicone rubber is a great PC/PMMA alternative. |

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

One of the most important applications of 3D Printing relating to automotive industry is weight reduction of components. Automotive applications make use of advanced engineering materials and complex geometries in an attempt to reduce weight and improve performance. AM is capable of producing parts from many of the lightweight polymers and metals that are common in the automotive industry.

There are wide variety of applications for 3D Printing in automotive industry. Below are some of the applications – (a) Weight final parts, (b) Complex geometries – prototypes & final parts, (c) Temperature – Testing & final parts (d) Moisture – Testing & final parts (e) Part consolidation – prototyping & final parts.

3D Printing is used for manufacturing Bellows, Complex Ducting, High Detail Visual Prototypes, Functional Mounting Brackets,

Material & technology used highly depends on the kind of part being 3D Printed. For under the hood parts, generally SLS 3D Printing is used as it is heat resistant; for interior accessories SLA 3D Printing is used; for air ducts, SLS is used; Industrial SLA is used for full scale panels; DMLS is used for complex metal components; Material jetting is used for manufacturing Bezels and finally, SLA is used for manufacturing Lights.

Latest News