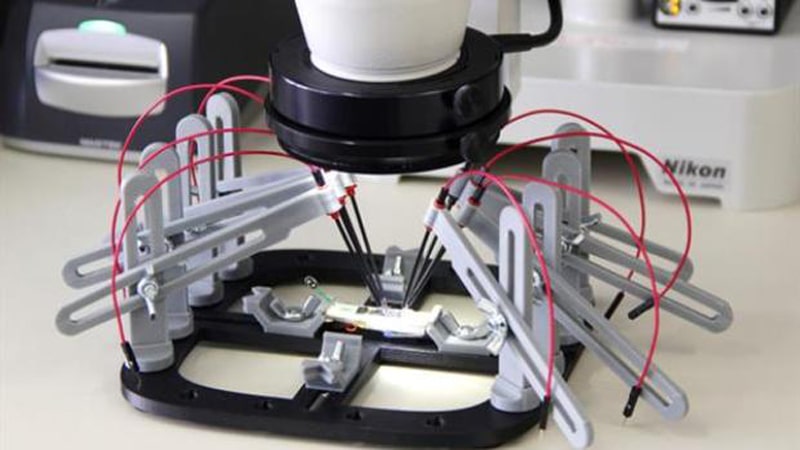

The 3D printed PCB workstation developed by creator Giuseppe Finizia, was released in 2015. He has published an updated version of his PCB project, which also has crane arms.

Giuseppe Finizia is an electronic forensic expert and engineer who had designed the PCB workstation in 2015. The Thingiverse community held high acclaim for Finizia’s design. The workstation, which gives circuit board tinkerers small articulated arms, has received over six thousand “likes”, and has been assisting thousands of projects where precise connections were required on a printed circuit board. Finizia has now published an updated version of the workstation with a stable crane arm system.

In the updated PCB workstation, users can adjust the arm position by rotating a full pin joint which acts as the elbow of the arm, and by adjusting the pivoting base. The previous workstation had arms with a ball and socket joint. The crane arm can make intricate moves over small points on the printed circuit. The tip of each arm has a needlepoint test probe, where users can attach LED, magnifying glass, and other accessories. What’s more, users who found the previous arms of the workstation easier to maneuver, can choose between either set of arms for their workstation.

The base of the workstation remains the same and both the versions were designed on the Mol CAD software. Finizia used a Zortrax M200, for 3D printing both the workstations, though they could be printed using any FDM printer. The printing settings that produced the original workstation: rafts, supports, 0.19 mm resolution and high infill are all similar in the new device.

Finizia’s workstation project demonstrates how 3D printing can be used operation PCBs. There could be a time in future where 3D printers are used to make circuit boards. Companies like Nano Dimension and VOXEL8 are using new technologies that would see additive manufacturing sync in with the electronics industry.