With the help of 3D printing, researchers at SPbPU has created an expansion turbine for electric generators. They have the ability to work on high-pressure natural gas. For the sustainable energy in Russia, this is a commendable step.

In spite of the fact that it’s really hard to go from one end of Russia to the next, living on the planet’s biggest nation has its advantages—on the off chance that you work in its oil and gas industry, at any rate. That is on account of the immense nation has a fittingly enormous supply of normal assets, including characteristic gas, that contributes incredibly to the nation having the fifteenth biggest economy on the planet by ostensible GDP. Right up ’til today, Russian researchers keep on finding better approaches for utilizing the nation’s wealth of normal assets in the most proficient way.

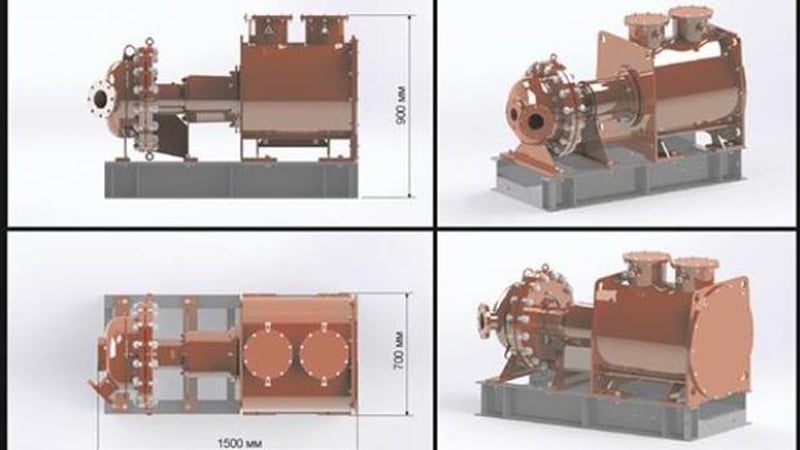

A week ago, researchers at SPbPU declared the advancement of a development turbine for a turbo expander electric generator that produces power from regular gas. The turbine is equipped for activating critical weight drop at a low volume stream of common gas with an electrical force of 1 kW, and is produced using 3D printed plastic parts. The somewhat 3D printed generator can change over piece of its discharged vitality (that would somehow or another be squandered and make contamination the earth) into usable electrical power.

“Regular gas stores and [the] created gas transport framework (GTS) foundation of Russia are a national fortune that makes the nation a pioneer in extraction and supply of characteristic gas—the cleanest sort of fossil fuel,” the SPbPU scientists say. “The operation of the GTS directly affects vitality, social, and monetary security; what’s more, Russia is the fundamental provider of gas to European nations. In this way, the modernization of the GTS is one of the principle bearings of legislative work.”

An imperative piece of the modernization of the national gas transport framework, the specialists say, includes utilizing new and imaginative assembling procedures to make each piece of a generator as powerful as it can be. In this exploration extend, the researchers found that, by utilizing adjoining contact shoulders to supplement a 3D printed plastic circle in the turbine’s fundamental wheel, they could decrease the anxiety incurred upon the plate by 25%.

In spite of the fact that the scientists utilized Nylon 12 for the focal plate in the turbine, they noticed that, by utilizing 3D Systems’ Accura Xtreme Plastic photopolymer 3D printing material and printing the parts on a stereolithography 3D printer rather, the parts could be made with an enhanced surface quality and expanded solidness. Moreover, parts imprinted along these lines could withstand temperatures of between – 30°C and 65°C. Additionally testing, be that as it may, would be required before SLA-printed parts could be utilized.