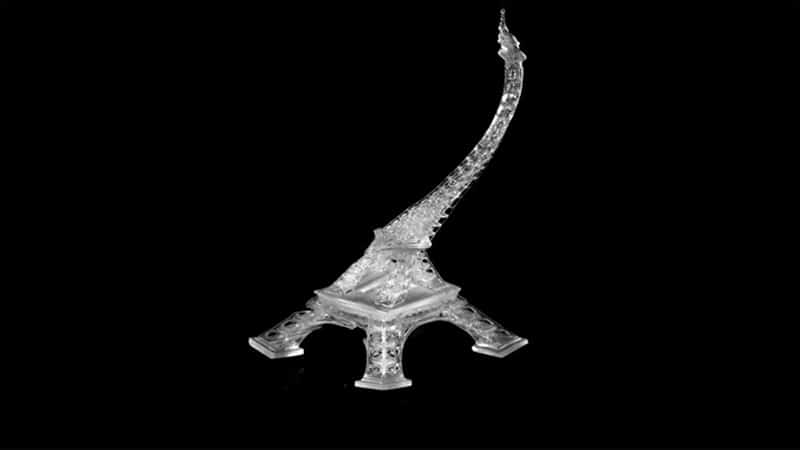

Image Source: 3d natives

Researchers at Northwestern University have developed a remarkably faster photo-polymerization-based 3D printer. This can deposit 4000 layers in just 2 minutes! But that’s not all: this is equipped with a robotic arm that moves during the printing process. Let us know how this dynamic 3D printing works?

We all are aware that the 3D printing process starts with the modeling of the desired final part, which is sliced into different horizontal layers. Finally the layers are deposited on the build plate in order to get the desired final structure. Depending on the machine used and size of the structure, the manufacturing process may vary. Northwestern’s team provided the ability to change the original design layer by layer and rotate the print direction without recreating the model. Cheng Sun, associate professor of mechanical engineering explains that ” The 3D printing process is no longer a way to merely make a replica of the designed model. Now we have a dynamic process that uses light to assemble all the layers but with a high degree of freedom to move each layer along the way”.

How does this process work ?

Cheng Sun and his team relied on a DLP 3D printer which is equipped with a robotic arm. This machine can alter the printing direction dynamically. It just functions like a classic resin machine and uses the heat of a video projector to cure a liquid photopolymer. The advantage of using this technology is, it can polymerise the entire layer at a time. This makes it easier for the system to run continuously and can print 4000 layers in two minutes. Cheng Sun added ” This is a very fast process, and there is no interruption between the layers. We hope the manufacturing industry will find benefit in it. The general printing material is compatible with a wide range of materials.”

This is one of the several additive manufacturing innovations to have come out of Northwestern University. Cheng Sun hopes to apply this methodology for the subtractive manufacturing process, which could offer significant opportunities for the manufacturing industry.