The success of a manufacturing technique largely depends on the material being used. Since we cannot use a large variety of materials for 3D printing, this technique is bound by limitations. Cost and speed are other considerations. But a new platform in China brings the carbon fiber into the 3D printing arena. The DB-F01 3D printer is a two-meter tall machine by Beijing Duoba Science and Technology. It 3D prints up to 4 kg of materials per hour and is capable of 3D printing high-quality functional objects.

So is pure carbon fiber 3D printable? This material is stronger than steel and aluminum and is widely used in the manufacture of cars, planes, and turbines. Carbon fiber requires large amounts of labor and is manually milled. This material cannot be printed on the regular desktop 3D printer. But with professional skill and expertize, this material has been successfully 3D printed by 3D printing service providers like Markforged.

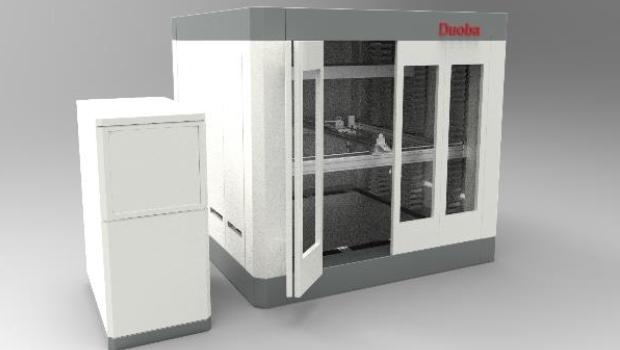

The DB-F01 3D printer from Duoba Tech is built by Chinese developers who had a vision of building a technology that supports large size, fasting 3D printing, strong materials, and large-scale projects. Two years thence, and the result is a 3D printer that can easily 3D print weather-resistant, weight-bearing parts of mammoth sizes, owing to a 1200mm x 1200mm x 1200mm build envelope. The DB-F01 is now available in the market.

The Chinese company went on to reveal that the 3D printer is the result of their independent R&D process, and they have patented their technology. With the DB-F01, 3D printing can be put to many more applications.

Its specifications are-

Size: 1890mmX1860mmX1780mm

Build envelope: 1200mmX1200mmX1200mm

Maximum height: 3.5mm-4mm

The fastest printing speed: 16mm / s

Printing temperature: 210 ℃ -275 ℃

Maximum printing weight: 600g / h — 4kg / h

Source: 3ders.org