The basic differences between Multi Jet Printing(MJP) and Poly Jet Printing(PJP) are in the build materials,their properties and post processing methods. Both of them be allied to Material Jetting Technology where the build materials(photo-sensitive resins) are deposited by inkjet printing process and cured under UV light. The differences are in varieties of materials can be build, surface finish, accuracy and applications etc.

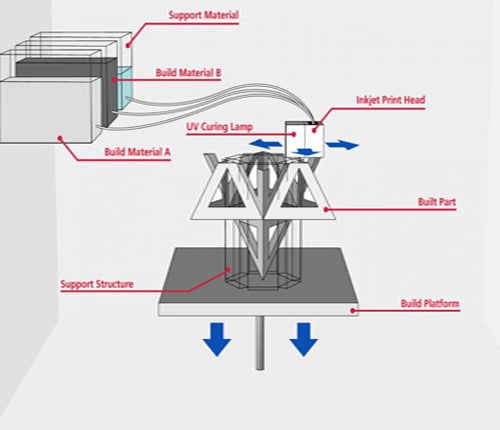

Multi Jet Printing(MJP) is resin based Material Jetting Technology where basic components are build material and support material. Using MJP we can print solitary variety of material, it is not possible to print multi material in a single build. MJP is used to build parts, patterns and molds with exceptional feature detail to mark a ample range of applications.

These printers are high resolution, economical and ease to operate. The support material are separate, meltable, dissolvable to make post-processing operation easy task. The post-processing operation is hands free operation helps to get complex, delicate features and easy to clean without damage. Post-Processing operations include convection baking, ultrasonic bath, mineral oil bath, rinsing with warm soap water etc.

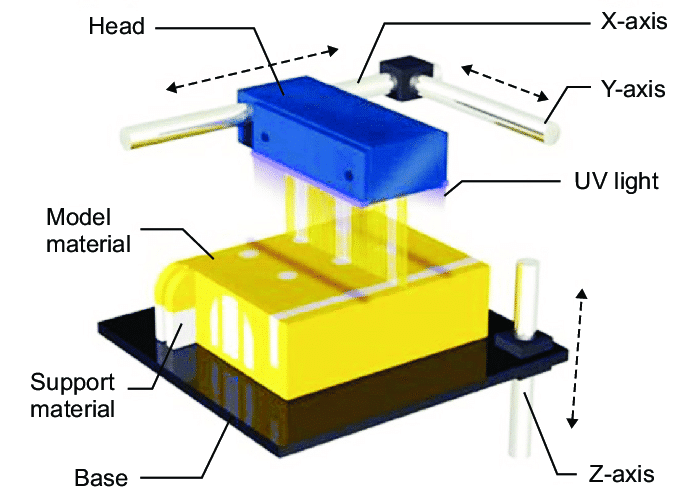

Poly Jet Printing(PJP) is also a resin based Material Jetting Technology where two or more jetting heads that deposit photo-polymer resin to build prototype. Using PJP we can print multi-material prototype in a single build. PJP is used for investment casting, prosthetic limbs,dental labs etc.

PJP printer produces precise, accurate and smooth finish.In PJP, not only standard photo-polymers but also build materials like clear, rubber, biocompatible and tough thermoplastics are used.The support material is a gel-like substance, which is easily washed away.Post processing operations like sanding, water jetting, lacquering are used to give aesthetic appearance.

Differences in Properties and applications

| Property | Multi Jet Printing(MJP) | Poly Jet Printing(PJP) |

|---|---|---|

| Layer Thickness | 0.032 mm | 0.06-0.08 mm |

| Build Volume | 294 x 211 x 144 mm | 255 x 252 x 203 mm |

| Accuracy | ±20 microns | ±30 microns |

| Build Material | photo curable resins(Visijet resins), casting wax materials | photo polymer resins(verro cyan, verro clear, tango etc.) |

| Limitations | confined to single color and material in single build, due to oil bath in post processing operation some of the properties of build material may vary | sharp edges are slightly rounded, support material creates alternatives in surface quality |

| Applications | Design of appearance and evaluation models, conceptual prototypes etc. | Prototypes for investment casting, multi-material,prosthetic limbs etc. |