Differences in technologies and materials

Selective Laser Sintering

Stereolithography

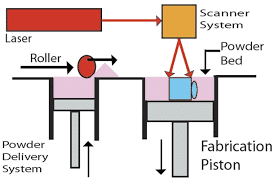

Selective laser sintering (SLS) is a rapid prototyping technique that uses a laser likely CO2 laser as the power source to sinter powdered material namely polyamide and polystyrene powders, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

In SLS technique nylon(namely polyamide and polystyrene) is used as build material. In this technique, the build material will be in powder state. This powder is fused selectively by a laser according to the data given at the time of design.

Stereolithography (SLA) is also known as optical fabrication , is a form of 3D printing technology which is used for preparing a prototype in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers. Those polymers then make up the body of a three-dimensional solid.

In SLA technique photo polymer resin(namely clear resin , castable resin, standard resin) is used as build material. In this technique, the build material will be in liquid state. This resin is cured,layer by layer accordingly by the laser that is beamed.

Differences in Properties

| Property | Selective Laser Sintering | Stereolithography |

|---|---|---|

| Build/Bed volume | 200x250x330 mm | 145x145x175 mm |

| Layer Thickness | 0.06mm to 0.12mm | 0.05mm to 0.15mm |

| Accuracy | ±100microns | ±50microns |

| Minimum Wall Thickness | 1mm | 5mm |

| Laser Type | UV laser beam | Co2 laser |

| Sensitivity | Long exposure to UV light damages the object | High Brittleness |

| Surface Finish | Very Rough Surface Finish | Smooth Surface Finish |

| Build material | Powdered nylon Resin(namely PA2200) | Liquid Photo-Polymers,Photo-sensitive resins |

| Post Processing | Dusting and possible Sanding | UV baking and removing support structures |

| Applications | Functional prototypes,short run,bridge or custom manufacturing | Patterns, molds,dental and jewellery applications |

Sample parts

Selectively Laser Sintering

Steriolithography

SLS(on left) vs SLA(on right)

FREQUENTLY ASKED QUESTIONS

Comparatively SLS will be low cost because of the price of build material and post processing techniques.

In SLA technology we will achieve better surface finish because of build material properties, output will be like moulded plastic part

SLS will be preferred because the build materials are typically nylon and hence tougher than average SLA resins

SLS has no chance to get clear output , whereas in SLA some resins are translucent and some are clear. To get clarity, you will need to polish the build part

SLS is used for manufacturing of hollow parts as there is no support generation required whereas in SLA support generation is a mandatory step, which will be tough to remove supports during post processing, in case of hollow parts