Introduction:

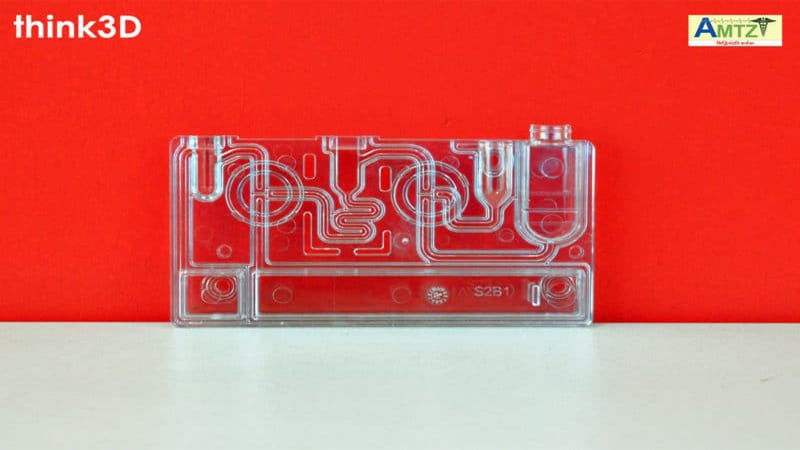

This article covers the process of manufacturing test cartridges through the injection molding process. The COVID-19 pandemic has changed a lot of things. This is an infectious disease and it affects different people in different ways. Some will experience mild respiratory illness and for others, it may lead to serious illness. So in order to save our lives, we should follow the necessary precautions. And should go for tests even if there are mild symptoms. Government is unable to provide sufficient kits for testing. As a result of this many are losing their lives. So we at think3D are manufacturing test cartridges for our client company Molbio Diagnostics Pvt Ltd,.a Goa-based company which has its production facility in the AMTZ campus. By using these cartridges we can get results within a short span of time.

Objective:

To deliver the product on time with quality and quantity assured within a stipulated time period.

Process of manufacturing :

We use injection molding technology for manufacturing test cartridges. Injection molding is a popular manufacturing method for plastics. The main step for manufacturing any product or prototype is designing. So to design the product, we have a software called CAD(Computer-Aided Design). With the help of this, we can design the product.

In the second step

- Polycarbonate granules are fed via a hopper and heated to a molten state at different temperatures.

- The molten plastic is injected through the nozzle into the core and cavity plates of the mold.

- The injected material is cooled and solidified before ejected from the mold.

Assembly of the Cartridge:

We have hired a dedicated staff of 30 members to assemble the cartridges with grommets(silicone washers) which is an additional service provided to the client company as requested.

After assembly, the product is sent to the client company to undergo clinical tests and then converted into a COVID-19 Test Cartridge.