ColorJet Printing has the unique capability of producing part directly in high definition colors, and offers a fast, cost-effective solution for producing complex geometries.

WHY CHOOSE THINK3D

think3D has one Projet 660 PRO 3D Printer from 3D Systems. We can offer various full color miniatures through this machine. We have the lowest price and quickest turn around time in the market.

Color jetting or binderjetting 3d printing process can produce high-definition, full-color prototypes or early-stage concept models affordably, and within tight deadlines. As models are 3D-printed directly in color, ColorJet allows you to analyze color variations at an early stage without having to spend the extra time and money for post-process painting.

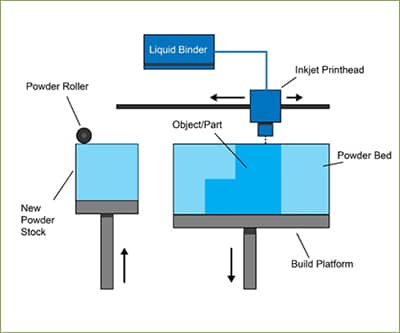

The process works by depositing a colored, liquid binder onto thin layers of powder. A roller mechanism spreads an even layer of white powder, the core material, across the build platform. The print heads then selectively jet the binder onto the powder to bind the subsequent layer of core material. The liquid binder serves the dual task of fusing the layers and coloring the part in a multitude of shades. As is the case with other powder bed systems, once a layer is completed, the powder bed drops incrementally and a roller or blade smoothens the powder over the surface of the bed, prior to the next pass of the jet heads, with the binder for the subsequent layer to be formed and fused with the previous layer.

The process works by depositing a colored, liquid binder onto thin layers of powder. A roller mechanism spreads an even layer of white powder, the core material, across the build platform. The print heads then selectively jet the binder onto the powder to bind the subsequent layer of core material. The liquid binder serves the dual task of fusing the layers and coloring the part in a multitude of shades. As is the case with other powder bed systems, once a layer is completed, the powder bed drops incrementally and a roller or blade smoothens the powder over the surface of the bed, prior to the next pass of the jet heads, with the binder for the subsequent layer to be formed and fused with the previous layer.

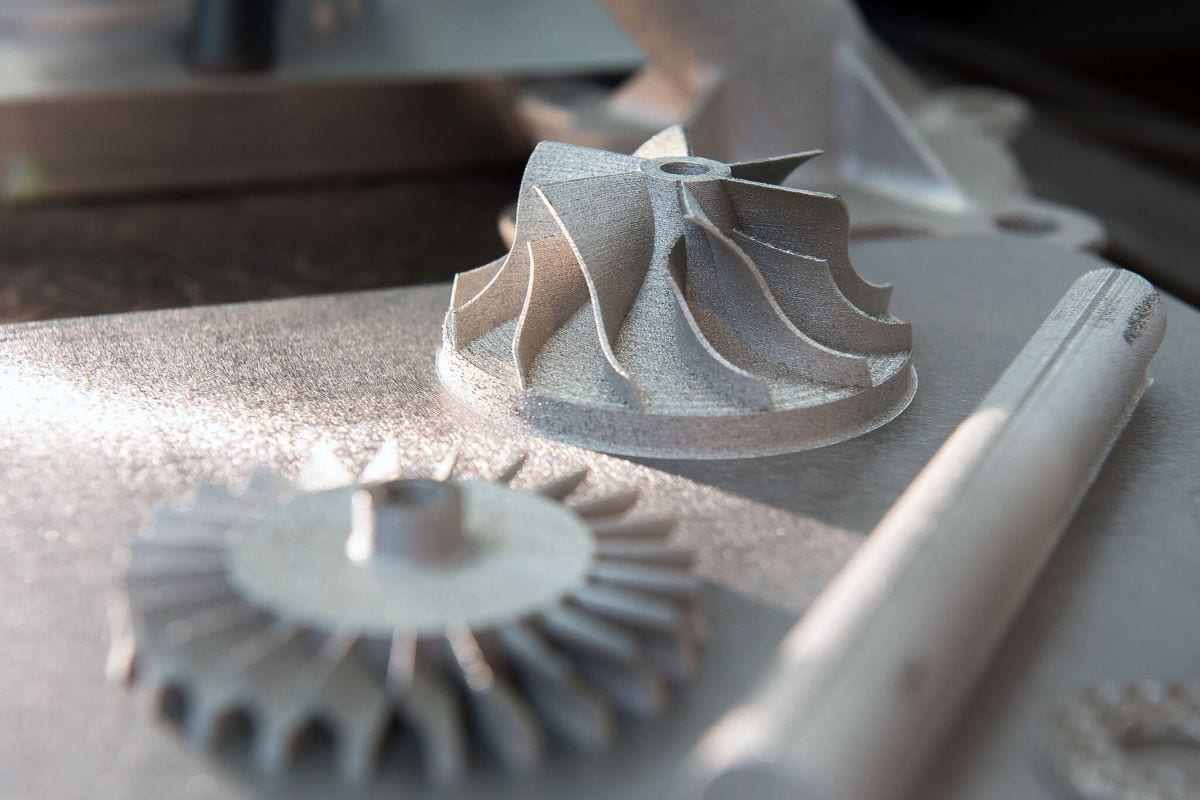

Advantages of this process, like with SLS, include the fact that the need for supports is negated because the powder bed itself provides this functionality. Furthermore, a range of different materials can be used, including ceramics and food. A further distinctive advantage of the process is the ability to easily add a full color palette which can be added to the binder. The parts resulting directly from the machine, however, are not as strong as with the sintering process and require post-processing to ensure durability.

The models offer rich colors but do not have hign strength, and are ideal for display and training purposes.

-

Miniature figurines

-

Architectural and industrial scale models

-

GIS / terrain models

-

Concept models

-

Display/ demonstration models

- Complex geometries

Sandstone powder View Data sheet

| Tensile Strength | Flexural Strength | Tensile Elongation at Break | Heat Deflection Temperature(°C) |

| 2,031 PSi | 4436 PSi | 0.2% | 233.6 |

Minimum Wall thickness: 2 mm

Minimum details size: 2.5 mm (for text/ hole diameters etc)

Layer thickness: 0.05 mm – 0.1 mm

Max dimensions: 254 x 381 x 203 mm

Standard Accuracy: ± 0.2% (with lower limit on ± 0.2 mm).

Lead Time: Minimum 5 working days for despatch

Surface finish: Grainy, sharp matt finish

Basic: Cleaning, Smoothing

Add on: Primer, Coating/ Painting