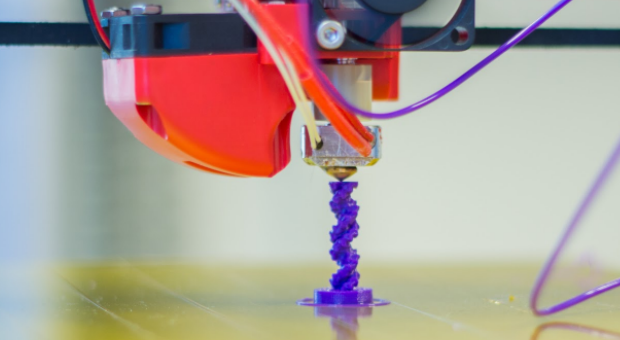

Autolift system developed by Dglass3D is the perfect and handy upgrade that we need in 3D printing. It is actually an engineering system that comprises of a micro linear bearing and spring that activates the retracted nozzle position. The system automatically lifts the nozzle during filament retraction which in turn eliminates the dragging and prevents the extra plastic from being deposited. The system is also adjustable which gives the user the extra benefit to fine tune the retraction amount depending on the project, material or the objectives of printing.

The key features of the product are:

- Plug-and-play groove style mount

- All-metal design for high temperatures

- Micro linear bearing for maximum durability and performance

- Compact design allows for simplified adaptability

- 1.75mm or 3mm filament

- 40w cartridge heater included

- 300º C thermistors included (500º C optional)

- 0.35 mm nozzle included

- Fan included Locally sourced parts, hand assembled by D3D team

- Thermistor & Heater affixed with setscrews without the need of a Kapton Tape

The idea of Autolift hot ends was conceived on a development process for the RUGGED HPX line of extruders which was funded on Kiskstarter earlier this year. After many tests the team found that the rigid mounted hot ends were capable of printing quality prints but the only problem with them was that they lacked the ability of imparting fine details or resolution while printing 2 colors. The reason behind this was that it could not fully retract and the end output of this fault was plastic stringing and deposits left on the print. This limitation was the reason behind this breakthrough. Now, Cofounders of Dglass3D, Brian and Carl hope to raise $10,000 on Kickstarter for the autolift, to allow them to purchase the volume of materials needed to keep production costs low.

Image Credit: Jonathan Juursema (www.jonathanj.nl)