Author: think3D Customer Care

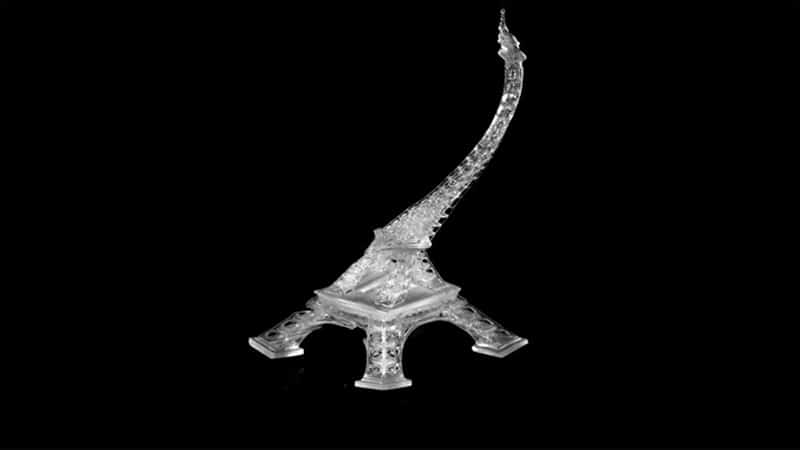

Breakthrough in Esophageal Cancer treatment thanks to 3D printed stents

February 15, 2021

No Comments

Read More »

Dynamic 3D printing method achieves unmatched speed and accuracy

February 10, 2021

No Comments

Read More »

Are the resins used in dental 3D printing dangerous for reproductive health?

February 9, 2021

No Comments

Read More »