Author: Raja Sekhar Upputuri

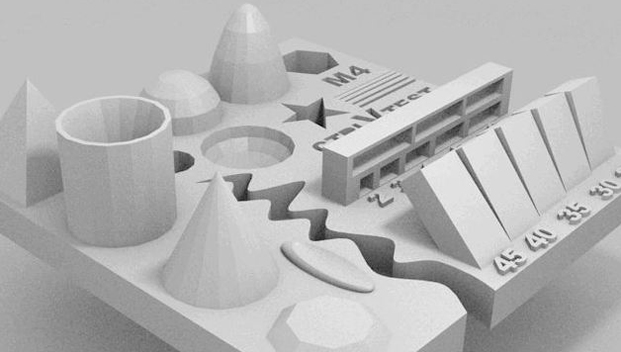

All-in-One Solution for Testing and Calibrating Your 3D Printer

March 6, 2015

No Comments

Read More »

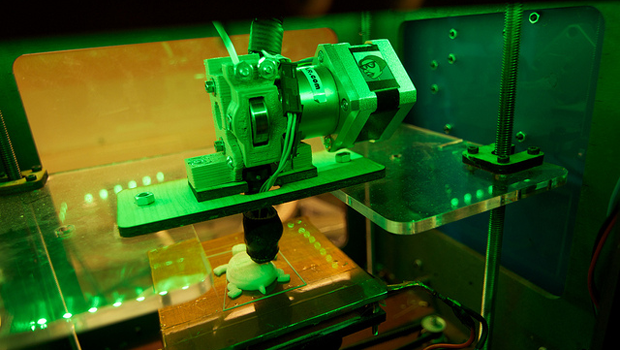

One day workshop on 3D printing technology at MVSREC, Hyderabad

February 18, 2015

No Comments

Read More »

SCANIFY, a new affordable 3D scanner from Fuel3D launched at CES 2015

January 22, 2015

No Comments

Read More »