In the urge to make 3D printer and CNC machines work better, alignG, a precision tool has been launched by Kickstarter. This campaign cost around $100,000. It is a portable and wireless machine with other features such as non-contact measurement. Ultrasonic energy is used for the operations of the machine.

The print quality of a printer greatly depends on the unset nozzle-bed gap. It is quite unfortunate that the exact size of the gap cannot be measured. Different sized gap results in different kinds of printing. If the gap is too small then the first is likely to get damaged. At the same time, if the gap is large then the prints will not b able to stick.

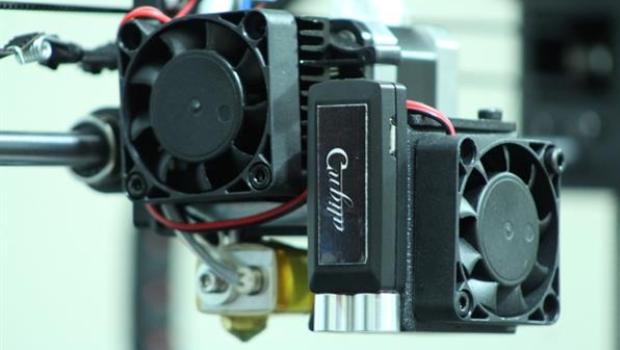

After so many complexities, the 3d printing experts have created alignG- an alignment tool for the 3d printers and the CNC machines. The usability of this tool in 3d printers is quite interesting. It can be used to monitor and zero Z-stage and make this tool a perfect item in the maker’s toolkit.

The Z-stage of the 3d printer can be analyzed and measured with the help of non-contact distance measurement sensor. Attaching the device to the printer’s extruder is required by the maker and the gap will be located via trial and error. Through the built-in display of the device, it will provide a see-through to the accurate gap distance. It is important for the makers to achieve print quality and proper adhesion.

The operations of the device are not limited to finding the Z-stage positioning. It is a versatile device that can be used for multiple other purposes. It is an amazing device that will surely raise the standards of the 3d printing industry in the world.

Source: 3ders.org