Two is better than one! That’s the attitude that we all carry similar is in the case of extruders. There are undoubtedly many positive aspects that are there in a dual extruder 3D printer but the other side of the coin is quite unimpressive. Some of these ugly facts are that there is a lot of difficulty in maintaining the flow over the two extruders and also the alignment should always be similar in the two extruders for a perfect print out. The other very persistent problem in these printers is the maintenance of the correct heat level in both the extruders which has to be checked throughout the printing process. The other issues consist of drippings, clogging, unwanted system shut downs and the list is never ending. Dual printers are not new to the market they have been there for quite some time now.

When there is a problem there is someone who undoubtedly comes up with a solution to solve this problem. A company named Airwolf recently announced the launch of their new printer named AW3D HD2x Dual Hot End 3D Printer. This is a printer which the company feels that would put a full stop to all the annoying problems that the owners of a dual extruder head printer have to face. The key element of the printer which is the JRx print head is installed in the printer. This print head promises to make multiple extruders printing a happy experience. These extruders have their own stepper motor and are manufactured as a single piece unlike other 3D printers. The co- founder and chairman of Airwolf, Erick Wolf 3D said, “Our ultimate goal is to place a 3D printer on every desktop,” explained Erick Wolf, Airwolf 3D co-founder and chairman. “To accomplish this we have to design and manufacture units that include the features customers want at an affordable price. Our new dual hot end AW3D HD2x is the latest example of our commitment and our most significant product ever. We’ve engineered it to be a simple-to-use, hassle-free 3D printer that combines the versatility of two hot ends with the desirability of printing over 20 different materials including polycarbonate and nylon. Basically, we’ve built a $10,000 desktop printer for a fraction of the cost.”

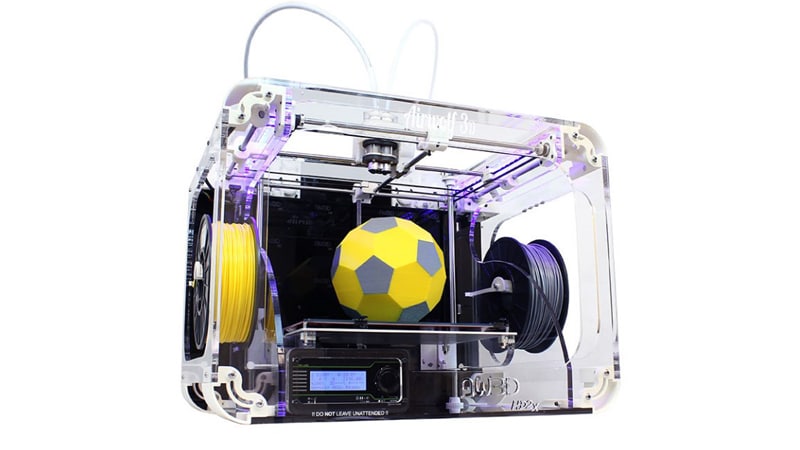

About the printer:

This printer can print in two different colors or two different materials at the same time. The printer has nylon gears due to which the printer has a longer life span as the wear and tear is minimal. The build dimension of the printer is 11″ x 8″ x 12″, having a printing resolution of 0.06mm and a speed of 150mm/s. The most amazing part of the entire printer is that the company actually knows how to get their customers involved as they has pretty awesome perks attached with the printer. Such as a free two hour training session at their facility in California, a spool of ABS filament, a flash drive with their software and a set of allen wrenches which are ideal for adjusting the hardware. The printer is priced at $3,995.

Imagecredit: airwolf3d.com