We can see 3D printing advancements in many fields. There are a lot of advantages of using 3d printing in medical sector. Due to its flexibility and customization it is more useful in health care. Now let us know about its benefits in detail.

Digital Manufacturing and Design Flexibility :

The process of 3D printing starts with the designing of three dimensional CAD files. Designing can be done via software, or using 3d scanning also we can design the required object by scanning. In both the cases there are numerous advantages for the designer, because they can modify or manipulate the files/models easily . So we can save development time and cost while modifying the existing model.

This kind of freedom is very important, while designing models related to human bodies. There is a flexibility to design and modify models.

3D Mapping and Prototyping :

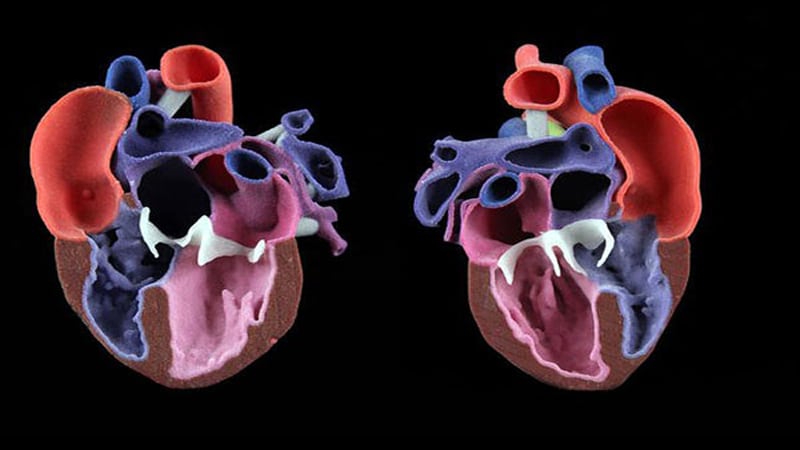

With the help of 3d scanning we can make highly accurate models of human. And these can be rendered as physical prototypes using a 3D printer. Doctors can practice on those models before going to perform operations, so that the amount of risk factor can be reduced. So in this way positive outcomes can be expected.

Finally doctors can plan advance surgeries on the models designed. This is possible only because of 3D printing.

Decentralized production :

We don’t need to establish large production houses or infrastructures for 3D printers. It’s so easy and simple to carry 3D printers because they are portable, we just need electricity and a computer. Due to this portability feature they are found in medical clinics and hospitals. They can be carried out to remote areas where there are no facilities. It is possible to fabricate prosthetics or simple parts in emergency situations when they are needed.

Optimized Engineering :

Many advancements are going on in the medical field to make plastic and metal parts. They use a wide variety of substances which have different mechanical and chemical properties. So parts can be designed with different characteristics such as rigid, flexible, soft etc. Few parts are for single use and others are permanent. With the help of the latest technologies we can fuse two components together into a single one.

Speed and Volume Flexibility :

3D printing is not limited to volume requirements, specialised tools, batch production limitations. If the design is ready then you can get the print at the single touch of a button. This type of flexibility is most used at the places where there is emergency and in remote areas.

Finally we can say that everything is possible with the help of 3D printing.

Image Source: star rapid