STEREOLITHOGRAPHY (SLA)

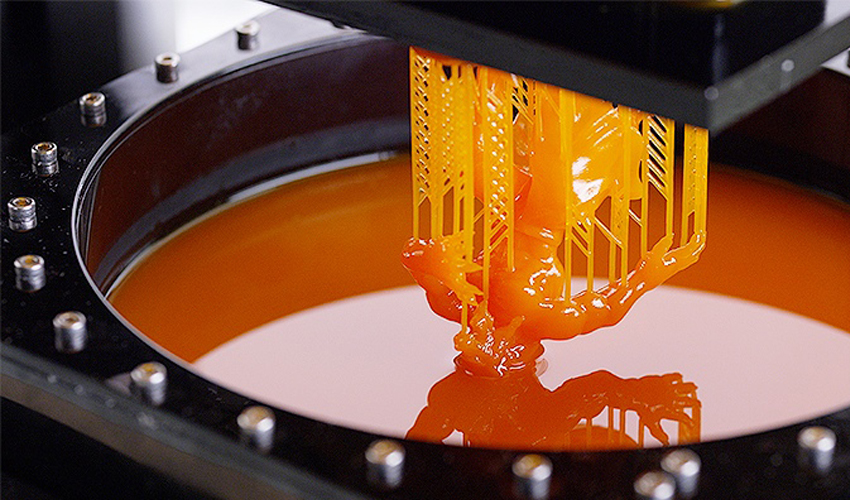

- SLA is one of the most precise 3D printing techniques on the market. Prototypes can be created with extremely high quality, with finely detailed features (thin walls, sharp corners, etc…) and complex geometrical shapes.

SLA 3D Printing service

think3D has 6 SLA / DLP / MJP machines of various resolutions and build volumes in-house. With these machines, think3D can offer some of the best resin based 3D Printing solutions to customers across various industries.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Overview

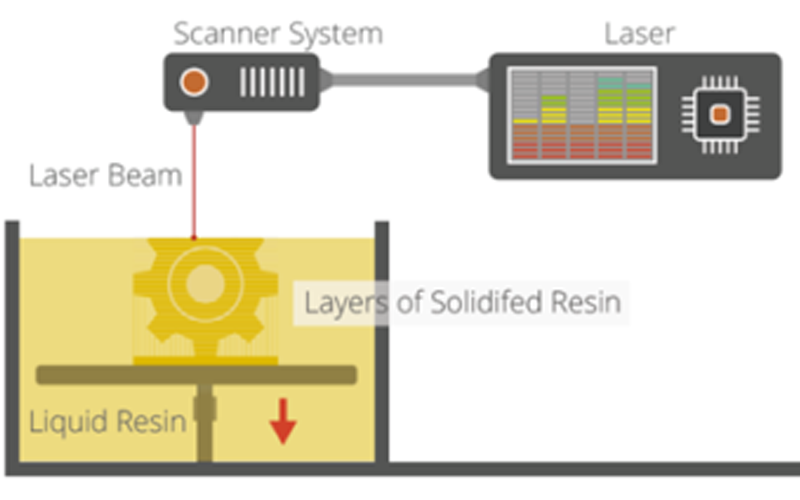

Stereolithography (SLA) is an additive manufacturing process that belongs to the Vat Photopolymerization family. In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. The materials used in SLA are photosensitive thermoset polymers that come in a liquid form.

SLA has many common characteristics with Direct Light Processing (DLP), another Vat Photopolymerization 3D printing technology. For simplicity, the two technologies can be treated as equals.

A laser beam is directed in the X-Y axes across the surface of the resin according to the 3D data supplied to the machine (the .stl file), whereby the resin hardens precisely where the laser hits the surface. Once the layer is completed, the platform within the vat drops down by a fraction (in the Z axis) and the subsequent layer is traced out by the laser. The resin that is not touched by the laser remains in the vat and can be reused. This continues until the entire object is completed and the platform can be raised out of the vat for removal.

Support structure is always required in SLA. Support structures are printed in the same material as the part and must be manually removed after printing. The orientation of the part determines the location and amount of support. It is recommended that the part is oriented so that so visually critical surfaces do not come in contact with the support structures

Applications

- Master copies for vacuum casting and other low volume prototyping techniques

- Patterns for investment casting

- Low volume/ limited edition products especially for complex geometries

- Dental/ jewelry/ art and other sectors which require high detailing and finish

- Visual prototypes for photo shoots and market testing

materials

Clear resin

| Color | Property | Tensile Strength(MPa) | HDT |

|---|---|---|---|

| Translucent | Rigid | 65 | 58 °C |

ABS like White resin

| color | property | Tensile Strength(MPa) | Melting Temperature°C |

|---|---|---|---|

| White | Rigid | 60 | 60 |

Grey Resin

| color | property | Tensile Strength(MPa) | HDT |

|---|---|---|---|

| Grey | Rigid | 65 | 60 |

Flexible Resin

| color | property | Tensile Strength(MPa) | HDT |

|---|---|---|---|

| 62.63 | 65.02 | 4.28 | 190 – 220 |

Castable wax Resin

| COLOR | PROPERTY | Tensile Strength (MPA) | Burnout Temperature |

|---|---|---|---|

| Green | Rigid | 11.6 | 249 °C |

Design Rules

Minimum Wall thickness: 1.2 mm

Minimum details size: 2 mm (for text/ hole diameters etc)

Layer thickness: 0.1 mm – 0.3 mm

Max dimensions: 650 x 600 x 600 mm. Large parts can be created with assembling individual parts by interlocking designs or glueing together.

Standard Accuracy: ± 0.3% (with lower limit on ± 0.3 mm).

Lead Time: Minimum 2 working days for despatch

Surface finish: visible layers with texture.

post processing

Basic: Support Removal, Curing, Sanding, Smoothing

Add on: Primer, Coating/ Painting

Clients

Think3D has been a great partner for us in supplying COVID-19 test cartridges on-time despite the pandemic challenges. When we came up with a new requirement needing a workforce of more than 25 people, think3D took up the challenge and arranged the workforce within 2 days. I highly recommend think3D for any manufacturing needs.

Sanket Srivatsav

Production In-Charge, Molbio

As a professor doing research on new materials, I needed a strong industry partner to assist us. think3D perfectly fit that bill. think3D team is highly knowledgeable on all manufacturing technologies and the team is very prompt in responding to all our requests. My research has been very successful, thanks to think3D team.

Dr. Karthik Chetan V

Asst. Professor, BITS Pilani

We found issue with one part at the time of assembly and needed a quick replacement. think3D team has quickly responded to our request, redesigned the part and printed it using metal 3D Printing and delivered in 3 days time. The part came out really well and the design was better than that of the actual one.

Rama Krishna

Senior Manager (IMM), BDL

Frequently Asked Questions

Yes, SLA parts can be milled, drilled, tapped or lathed

SLA is slower than FDM because the SLA printer’s laser has a smaller surface area and takes more time to complete each layer. In FDM, the printer can print thicker layers, which results in a reduction of time.

SLA uses laser to cure liquid resin where as DLP uses UV light to cure resin.

30 to 140 microns

In SLA multicolor is not possible. We can print multicolor parts in PJP technology in Think3D.

Since SLA parts are UV cured photopolymers, they don’t stop reacting to light once fully cured. Over time UV exposure will actually cause the parts to start to break down. This break down can weaken mechanical properties and cause parts to yellow. SLA parts are generally not suitable for environments with extreme daily sun exposure over a period of months or years. A good UV clear coat or paint can limit or prevent this breakdown entirely.

No. If we perfectly do sanding on support surfaces there will be no marks or bumps.

Yes, we can stick SLA parts. But not applicable for flexible resins.

Yes, Photocurable resins used in SLA are costly than FDM filaments & SLS powder. But with that extra amount we get superior surface finish in SLA.

3 replies on “SLA”

Hi, I have a small and details sample. which is 20mm x 20mm x 20mm and the minimum wall thickness in my model is is 0.4mm. Is it suitable to use SLA? or SLS? I also want to ask, in terms of strength which one is better either SLA or SLS? Since I’m looking for materials and fabrication technique that can produce my model perfectly with high strength.

Thank you

Hi, please send the design to info@think3d.in. Our team shall go through that and get back to you with the feasibility.

Hi, I have a small specimen supposed to be transparent, 100mm x 50mm x 10mm and channels with small diameters in the order of fractions of millimeters. Can SLA or SLS be used? I’m looking for materials (maybe PDMS or PMMA) and fabrication technique that can produce enough strength to have sufficient stiffness and be dimensionally accurate and also be handled repeatedly.

Thank you