3D printers are like the magical portals between imagination and reality, enabling us to see our dreams come true. Especially in the creative world, 3D printing has a great role to play, as it helps the creator’s ideas to take shape. 3D printers are the best solution for creative outfits like studios, filmmakers and game designers as it offers quick and agile fabrication. The following are steps that are necessary to prepare a render/animation-ready model for 3D Printing are explained in an elaborate manner in this article. It is very necessary to follow each step very closely and carefully.

Steps for 3D printing: DIY!

Design for your material

The model does not exist in real so the material that is to be used should be chosen very carefully. The material depends on what exactly you want to print. Many people want their characters to be in color the best option for such people would be full color sandstone. Using this material enable the end user to get a model that is in color. Some people look for affordable and versatile material for proto-typing or if the design requires interlocking parts. Such people should try the strong & flexible nylon plastic. So we see as the requirement change so does the material.

Weight distribution

The distribution of weight is the most important part of 3D printing models. If the requirement is that of keeping the models standing and not falling over then make sure that the bottom of the model is strong.

Sizing is another important factor. Sizing of the model to suit your needs as well as the printer is very necessary. Based on the material the size might change during production. Some materials experience shrinkage like Brass, Bronze, Silver, and Steel.

Mesh should be water tight

A water tight mesh can be achieved by closed edges creating a solid volume. It is necessary to check the normals and make sure that they all face outwards. Any normals that are flipped will be read as holes by the printer.

Be careful of protruding appendages/ thicken vulnerable areas

There are chances that the protruding or outstretched appendages might just snap off during or after the printing is done i.e. if the point of contact or the joint to the main structure is too thin. For example if you are printing a cat, pay close attention to the vulnerable areas, such as where the cat’s tail connects to the body, the thin ears, and legs, etc.

Hollowing the model with escape holes

The price of the material depends on the material that is being used. Hollowing the model will considerably reduce the price of the model from $17 to as minimal as $3.

Separate and Interlocking Parts

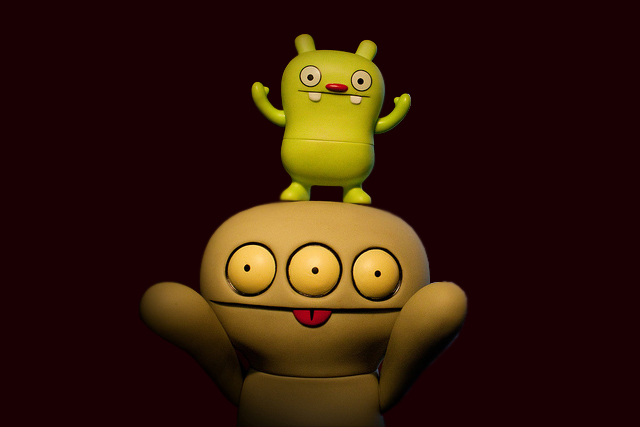

3D printing allows the creation of intricate, interlocking, movable pieces without assembly. The level of intricacy and detail is unparalleled. If the finished product is to be larger than the printer bed or if a puzzle or a toy is to be made, then this can be done by printing separate parts that can interlock after printing.

Clearance

If separate or interlocking parts are to be printed then it is very important to make sure that there is sufficient distance between tight areas. Production techniques such as SLS make moving parts without assembly possible. With the help of this technology enough clearance can be created so that the models pieces do not fuse together or trap support material inside.

Remove Smoothing Modifiers

When creating organic forms in 3D modeling software, it is necessary to start with a low poly mesh for easy changes and fast building. To create this, a smoothing modifier for faster render time is to be used. 3D printers do not read smoothing modifiers so it’s necessary to modify it in the software that s being used. After this the model has a higher resolution.

Export in Readable Format for Printers

When the 3D image is ready to be printed, a readable format is needed. STL is the most common and in some cases a plugin may be needed so that the file can be exported. This totally depends on the 3D modeling software.

Print and Share

Now the sole step left is to print the model and show it off!

The process to prepare a 3D model is a bit difficult but we hope these steps shared will help you to get a better understanding 3D printing process.