Researchers at the EPFL Lab for Bio and Nano Instrumentation are used 3D printing services to develop microscopy sensors and cantilever for the future applications.

Direct-write nanoscale printing of nanogranular strain sensors for sub-micrometre cantilevers, is a work by Maja Dukic, Marcel Winhold, Christian H. Schwalb, Michael Huth & Georg E. Fantner, Jonathan D. Adams, and Vladimir Stavrov. This research team outlines their latest 3D printing achievement at the nanoscale. They have developed a 5-nanometer thick sensor for their specialized cantilevers. They have also developed real world applications where they’ve put the sensors to work in for atomic force microscopy.

Atomic force technology is a powerful microscopy. It is described as functioning in a method to a small turntable with the cantilever’s nanometric tip pointing to one atom at a time. This is recorded by a sensor that allows the topography to be read. The research team at EFPL knew they needed a sensor that could allow them to read further on the level of the nanoscale. With size reduction, they would be able to increase both the sensitivity and detection of the sensor. This technology would be helpful to them, and at the same time, this ‘nanocharacterization and bio-sensing’ is valuable to other fields as well.

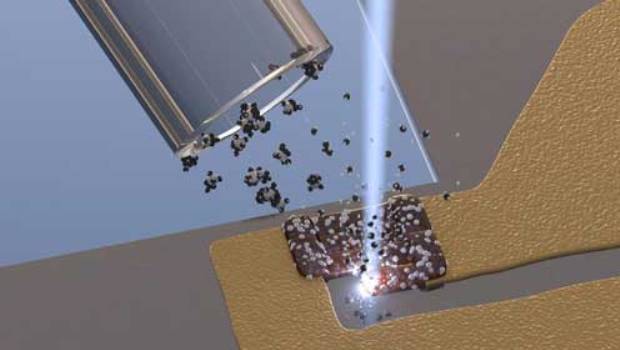

For developing the new sensors the material and the size were a huge consideration. The researchers were working with Michael Huth’s lab at Goethe University Frankfurt, to create sensors fabricated with platinum nanoparticles. These are highly conductive and surrounded by a carbon matrix that acts as an insulator. But these nanomaterial electrons could travel through the insulation and then go from one nanoparticle to another. The sensors were scalable to a desired height and width too. The team, hence, manipulated the structure and the properties of materials being used. The researchers were finally successful in crossing all hurdles and developing the sensors to their liking.