The biggest advantage of 3D printing is that it would cut down on the time taken in the manufacturing process. But even with this technology the assembly phase cannot be accelerated especially in the manufacturing of complex structures like airplanes and drones.

BAE Systems, the UK-based defense and aerospace giant, is getting it geared for the Farnborough International Airshow. The ideas of the researchers were welcomed about the future of aircraft. The scientists and researchers have envisaged a future where unmanned vehicles will be used widely, the execution of which would be largely based on chemistry and large chemical baths as concepts.

And these technologically advanced drones would be manufactured completely in just a few weeks.

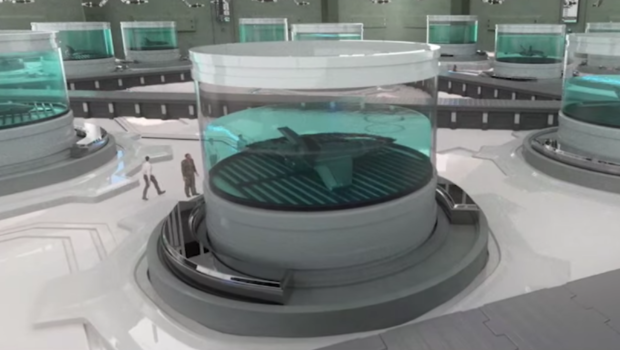

This collaborative process would require joining hands with other tech companies and develop a powerful 3D printer called ‘Chemputer’. This 3D printer would work by manufacturing the drones at the molecular level. The raw materials would be introduced into the chemical baths and centrifugal forces would be applied. This could lead to the formation of planes and the same principles could be applied to developing bigger aircraft.

Lee Cronin, the Regius professor at the University of Glasglow, Founding Scientific chairman of the Cronin Group, PLC, said that they were at the point of developing exciting products through chemical applications. Creating small aircraft would lead to the conceptualization of developing real airplanes in future.

BAE Systems is positive that the aircraft and military equipment could be built using environment sustainable resources and experiments and processes have begun in this field. These ideas are channelized towards developing military and aerospace equipment, but the same concepts could be applied to the civil aviation industry. Chemical 3D printer could be eventually used to manufacture furnishings, cars, electronics and many more products.

Source: 3dprint.com