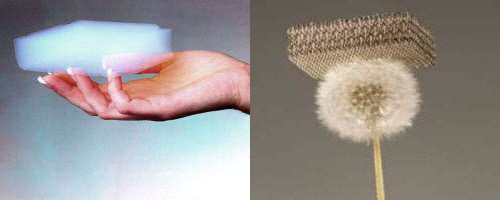

Aerogel is a synthetic porous ultralight , low density material derived from a gel, in which the liquid component of the gel has been replaced with air. The lightest among the areogels are Graphine Aerogels . Graphine aerogels are so light that a large block of it wouldn’t balance on a blade of grass.The minimal density of aerogels gives the scope for wide range of applications such as bio mimetic nano composites, tissue engineering, actuators, shape memory materials and so on.

Now, State University of New York (SUNY) at Buffalo and Kansas State University scientists report in the journal ‘Small’ that they have found a way to 3D print graphene aerogel, which has only been used in lab prototypes. This technology will make the material much easier to use and has many applications.

Graphene is typically a single layer of carbon atoms known for its strength, pliability and conductivity. Graphene aerogel is highly compressible and highly conductive material having several other properties, however, makes it difficult to manufacture using 3D printing technology.To 3D print the aerogels, polymers are mixed to it so that it can be pushed out using inkjet printers. Once the structure is done, the polymer is removed by a chemical process.But, removal of chemical may not be possible in case of graphine aerogel as these aerogels are very delicate.

SUNY Buffalo and Kansas State University scientists had an new idea to overcome this problem. They mixed graphene oxide with water and deposited layers on a surface at -25°C. This froze each layer in a jiffy, and allowed complete construction of the aerogel, with ice as its support.

Once this process was completed, the ice was removed using liquid nitrogen in a “freeze drying” technique. This expelled the water without damaging the micro structure. The material was then heated to remove oxygen atoms, which left only graphene in the aerogel.

3D printing creates objects in the exact shape and form as needed, which helps with rapid prototyping and adoption of new technologies. SUNY Buffalo and Kansas State University researchers are now looking to expand their 3D printing technology to build other types of aerogels.