Parts Produced

Machines In-House

Customers Served

Contact Us

Why Choose Think3D

Turn your ideas to reality with our full fledged 3D Printing, CNC Machining, Casting & Molding service capabilities. Our facility is equipped with entire range of 3D Printing technologies, 10 CNC Machines, 2 Injection Molding Machines and have a passionate team to serve you.

Quick Online Quote

Upload files in Get Quote section and get quote within 4 hrs

Technical Competency

Technically qualified team in various mfg. technologies

Competitive Pricing

Highly competitive price and bulk discounts also available

NDA & IP Protection

All designs and data are kept in highly secure private server

Our Kolkata Clients

INDIA’S LARGEST INTEGRATED

Digital Manufacturing Facility

Feel free to contact us if you wish to avail our services.

Frequently Asked Questions

3D printing is an essential tool for accelerating the prototyping process. However, its applications stretch well beyond prototyping to other facets of the product lifecycle.

• Manufacturing – Design freedom and economically viable low-to-mid-volume production enable new possibilities for product design and operational improvement. Applied in combination, these two capabilities have the potential to transform decades-old supply chains and business models.

• Tooling – 3D printed tooling advantages include on-demand production, customization, digitization of designs and unrestrained design flexibility. This cuts out costly suppliers, compresses lead times, enables digital warehousing and accelerates manufacturing floor productivity.

• Sales and Retail – 3D printing gives retailers the ability to innovate, delivering highly customized, on-demand products and new experiences such as “co-designed” items developed in conjunction with the customers.

• Aftermarket Supply – Businesses that embrace 3D printing for spare and replacement parts can replace warehouses of spare parts with 3D printers or a contract 3D printing service bureau to produce parts on a just-in-time basis.

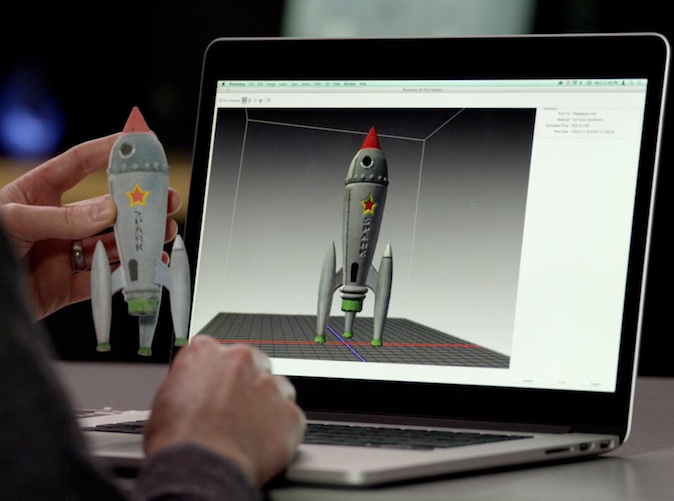

3D printing accelerates the process by reducing the time and cost associated with prototyping and refining the design. Many more 3D printed prototypes can be produced in the time needed to mold or machine them and for much less cost. Highly realistic prototypes printed on full-color multimaterial printers look like the final product, cultivating faster and better decisions.

3D printing gives designers the capability to drastically shorten the design process compared to traditional methods of hand-modeling or outsourcing to model shops.

Keep the design process entirely in-house. With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

Prototype faster and smarter. Outsourcing is often too expensive and time-consuming to allow iteration of more detailed prototypes, especially models that incorporate CMF (color-material-finish). The speed and streamlined workflow of 3D printing gives designers the freedom to create dozens of detailed prototypes while reducing the time to arrive at the optimal design.

Create beautiful, highly detailed models. With full-color, multimaterial printing, designers can create prototypes that look, feel, and even function like the real thing in just a few hours. The ability to assess the color, texture, and ergonomics of a product means better feedback and faster approval from clients.

3D printing is not a wholesale replacement for existing manufacturing methods like molding and machining. Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

Contracting with a service bureau to make your 3D printed parts is a good way to get introduced to the benefits of the technology. You gain the expertise and insight of a 3D printing specialist who can possibly guide you in optimizing the use of the technology for your specific purposes. Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Additive manufacturing shows promise for the defense, energy, aerospace, medical and commercial sectors. Its alternative approach to machining, forging, molding and casting makes it a good choice for rapidly making highly customized parts. The technology also shows promise for creating parts on site, such as at forward-stationed military bases. Because of its potential, many companies are using the technology to get themselves into a position to use it. The growing field of companies using the technology includes makers of machine parts and novelty items.

We’ve been in the business of helping customers solve problems for over 8 years with our 3D printing solutions. We can help you determine what technology is right for your application, whether a printer or a service bureau is more appropriate, as well as answer any questions you might have.

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.

- Freedom to design parts and sub-assemblies for the design, not for the manufacturing processes (DFM*)

- Have inventory on demand for both production and spare parts

- Eliminate costs of inventory and the time lag of supply chains

And!

- Gain the ability to quickly prototype with the same process with which you will manufacture — true rapid prototypes!

There is no printing facility in Kolkata but we serve for customers in Kolkata also as per the requirements.

Latest News

4 replies on “3D Printing Service in Kolkata”

What will be it cost to design a 6 inch ladder and print in 3d

As part of CSR activity, we want to make two numbers designer dustbins (1 no. 3 ft height and 1 no. 1 ft height). We will prepare the drawing and we want to get it printed thru some 3D printing agency. Want to know the costing details and the process for getting it printed in 3D. Material should be plastic/fibre.

Kindly provide a working contact number for communication. Looking for a 3d scan.

Dear Mr.Saran, Thanks for contacting think3d. Our contact numbers are 8142896564, 6305174938 and our mail address info@think3d.in.