Mr. Zhang, a 65 years old patient in China just got his hand replaced with a clenched fist. It has been reported that the patient has hematencephalon. His condition made it pretty difficult for him to hold a paper even. In the urge to get things right, Mr. Zhang received manipulative therapy and a 3d printed brace was give to him. All the work was done by the rehabilitation department of Zhongda Hospital.

On the scientific note, before creating a 3d model, the 3d data is scanned by a 3d scanner. In this case, the patient’s CT scan data and magnetic resonance is inputted into the system in order to make the brace of higher precision.

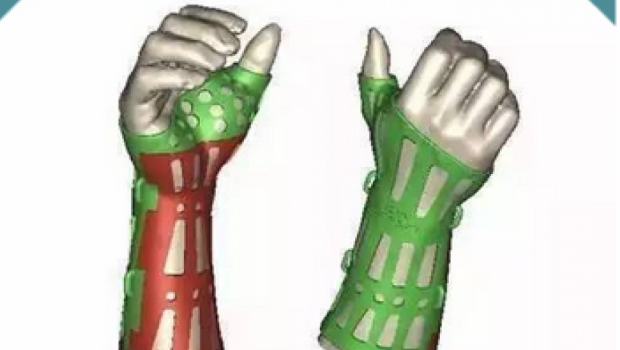

The process that is followed to create a traditional brace is very different. Also, the traditional brace is not very accurate. On the other hand, 3d printed braces are designed adeptly. All it need is for the orthopedic doctors to collaborate with the 3d designer, explain the design and help in the process of creating a perfect design.

Here are some of the prominent differences between traditional brace and the 3d printed brace

• Time taken in the creation of a 3d printed brace is 6 to 7 hours whereas the traditional brace requires at least 3 days.

• Smaller details are kept in check while creating a traditional brace. A 3d printed brace can be created with ease as the data about the design is fetched from the scanner

• A 3d printed brace fits better with the affected limb than the traditional one.

• 3d printed brace is lighter and more comfortable to wear since the design is made accordingly. At the same time, in a traditional brace, the holes for the air to pass have to be created by the orthopedic doctor. This makes the design heavier than the 3d printed design

• About the appearance, the design created with the help of 3d technology is neat and accurate where traditional one looks boring. The 3d printed braces can also be created with any color you like and with beautiful graphics on it.

With the help of 3d industry, lot more revolution is expected in coming time.