Just like 3D printing, parallel methods of creating consumer goods have emerged. But none of the other methods and tools has been as successful as 3D printing. A standard open-source 3D printer can now be converted into a laser cutter, as per the New Instructables released.

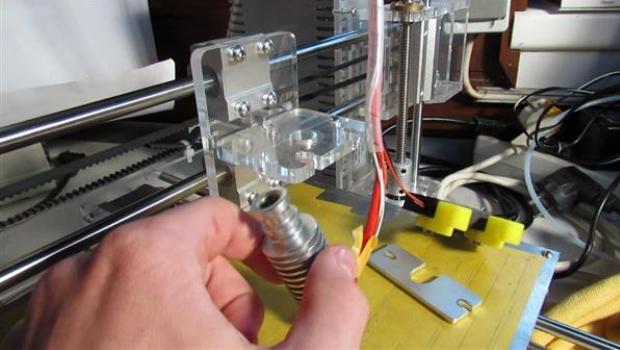

This trait can be achieved for a mere $40. The hot end of the 3D printer has to be removed. The new parts to be added is just a 500mV 505NM which has to be swapped with the 3D printer extruder. The laser will then be fitted into the printing machine. While demonstrating the working of the machine, Instructable user Jakes Workshop replaced the extruder fan with the laser by cutting some zip ties. Screws were used to fix the laser. After the laser electronics were wired into the printer, the user can download the laser driver software, for e.g. Inkscape and its plug-in. The x/y limits are thereby defined and the laser is concentrated on the z-axis. Finally, run the g-code for cutting.

The 500mW laser, though, cannot cut through heavy duty plastics and metals. The device can be used for engraving and cutting paper. The user should know the property of the material that he is cutting so that he can use the instrument precisely. The laser cutting device must be used for cutting materials that can be handled easily and the toxic fumes emitted can be minimal.

So, if you want a low-cost laser cutting gadget and are equipped with a 3D printer, this Instructable is a great option. For people who want a better laser option, the Endurance has a specification of 2.1 Watt laser module which is available for $195. This DIY laser cutting printer should be, after all, used with care as a laser is a difficult cutting device.