With 3D printing touching the pinnacles of success, latest buzz has been shared in the market about its upcoming invention. Robotics researchers at Stanford University have used 3d printing and created a microspine gripper system that will help a rock climbing robot to climb vertical surfaces with ease. A spider bite is no more required to climb up the walls.

Now having firm gripping is highly essential for a machine to hang on the vertical surface. Therefore, another system is in the development stage that will possess minute spines. These spines will make climbing easier for the robots and will also give them better grip to hold on to any surface type.

Climbing robots are not new in 3d industry. It’s been more than a decade since first the idea popped up in this industry. But, the robots that are been created at Stanford University are more versatile and they can support 4 times more weight. These robots have the tendency to pick a lot of weight, even though the spines that make the grip on the surface are too tiny.

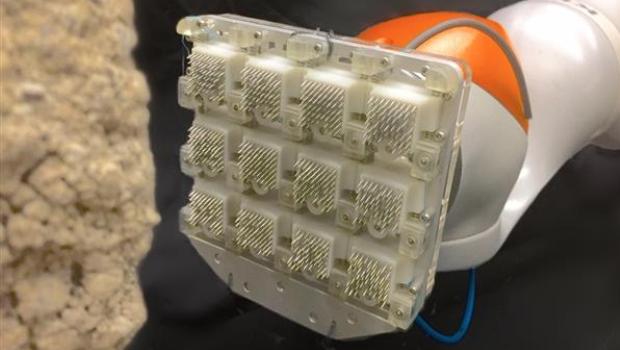

The quadrupling of proficiency as of now said was accomplished by utilizing a solitary consistent pivot, each 18mm x 18mm 3D printed tile holds 60 spines and in the event that you put 12 of these tiles one next to the other you have a ton of grasping force all while having a little squirm room between the parts to draw in onto any surface with more quality.

Also, since the greater part of the spines are calculated marginally in one course, the hold is effectively surrendered by pulling back outward on the inverse edge and bearing (not at all like other grasping strategies like velcro where the hold is dependent on an apparently confused chaos of sticking paws). Truth be told, up to 710 N of attachment was economically accomplished amid testing.