Anthony Garofalo, a person who 3D printed a stepper motor, has made a yet another breakthrough in 3D printing by adding LEDs on it to show how exactly the motor works. The educational project dubbed Axial Flux stepper motor, is focused towards informing others about the working of the stepper motor. The effort is primarily focused toward empowering the school and college going students about the functionality of stepper motor.

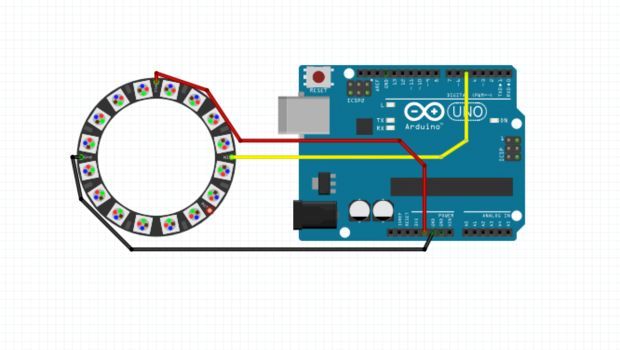

Garofalo’s project is inspired by a pulse motor video and stepper motor was designed. Later on, Garofalo took the initiative to 3D print the motor by using Utilmaker 2 3D printer. The other parts that have been used in the project include a compass to assess the magnetic poles,magnet wire, Arduino Uno,608ZZ bearing,some glue, electrical tape,four transistors,6 1/4″ neodymium magnets,8 8d 2-3/8″ nailsand16 NeoPixel LED ring from Adafruit.

The LEDs light up on the start of the motor. The LEDs have been placed to show as which of the coils are activated at the ignition of the motor. The ignition of the motor follows 15-degree steps. Besides, activating a couple of coils at a time can make the motor capable of half stepping. The entire process on how stepper motor starts has been explained elaborately by Garofalo through the LEDs.

Garofalo’s project is entirely an education project which is believed to help students in a long run in learning about the electronics that are used by us in everyday life. The details of the stepper motor LED project is available on Thingiverse. Garofalo is a UCF graduate and he also has experience of working with NASA. At NASA Garofalo got to know about different aspects of 3D printers. While working with the NASA Garofalo got inspired to use 3D printers in his projects.

Source: 3dprint.com