Introduction: Did you know that hearing aid industry was one of the first sectors to employ 3D printing in mass production? Most of the hearing aids are 3D printed. Based on a survey there are 10,000,000 3D printed hearing aids worldwide. One of the major issue with hearing aids is that prolonged use can cause ear infections. So in order to overcome this problem the researchers found a new solution. The antibiotics are directly injected into the hearing aids, which can release the drugs into the ears over a two week period. The technology behind the manufacturing of hearing aids is DLP(Digital Light Processing).

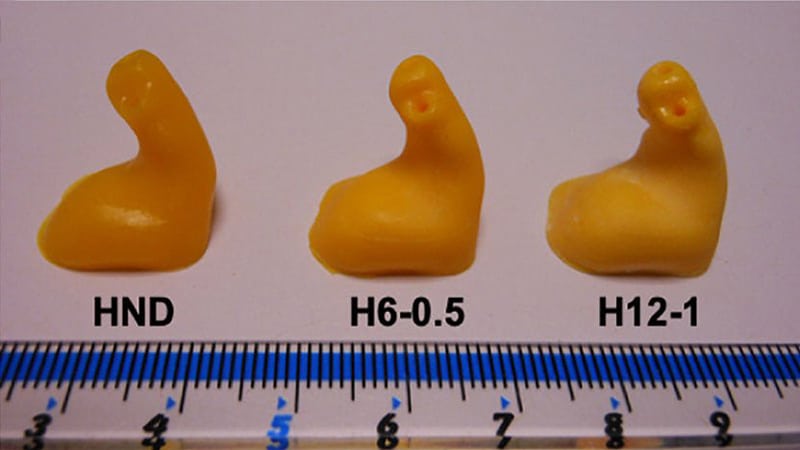

Here the antibiotics are ciprofloxacin and fluocinolone acetonide. The devices used here are proven to be robust and non-toxic. This aids are produced with two photopolymer resins such as ENG Hard and Flexible. These resins have high resolution and high quality surface finish. The antibiotics are mixed directly into the resins and printed using a resin based 3d printer. After manufacturing the devices are washed and cured to remove any uncured material or parts. These hearing aids were unaffected by the addition of antibiotics and release drugs for more than two weeks.

Conclusion: 3D printing technology has given solutions to many problems that we are facing today.